Why Xypex for Water Treatment Structures

Meeting the Challenge

Protecting Water Treatment Structures

The structural integrity of holding tanks in water treatment plants depends entirely on the protection of steel reinforcement from corrosion. Inadequate waterproofing, cracking, joint-failure, and chemical attack are problems that will result in the deterioration of concrete. The consequences are costly rehabilitation and significantly reduced service life.

With over 50 years of experience in 90 countries around the world, Xypex has extensive experience in the waterproofing and protection of municipal infrastructure, and is recognized as a key player in the water treatment industry. Our non-toxic Xypex Crystalline Technology has been officially approved around the globe for use with potable water, and has a vast portfolio of international project references. Whether used for new construction or the rehabilitation of water treatment structures, Xypex has gained an exceptional reputation for resisting extreme hydrostatic pressure, chemical attack and protecting the structural integrity of concrete.

Xypex products play a major role in the waterproofing and protection of concrete against hydrostatic pressure, cracks, joint-leaks, chemical attack and surface deterioration – problems typically encountered in the various concrete structures found in the water treatment process.

Hydrostatic Pressure

The waterproofing and protection of concrete in water treatment structures has two primary objectives:

To prevent water held in the structure from leaking out due to the hydrostatic pressure and to protect the reinforcing steel from corrosion.

The nature of concrete and its installation means having to deal with permeability problems created by the natural porosity of the concrete as well as defects (cold joints, honeycombs, rock pockets and tie-holes), joint leaks, freeze/thaw damage and drying shrinkage cracks. These problems typically leave the structure open to active leaks and accelerate the possibility of reinforcing steel corrosion and surface deterioration.

Additional Challenges

Chemical Attack

The addition of coagulants or flocculation chemicals such as iron salts, aluminum salts, or polymers creates an additional long-term problem for the concrete that can lead to surface deterioration. With a loss of concrete cover, the reinforcing steel in the structure becomes more susceptible to corrosion, deterioration, and ultimately results in the failure of the structure itself.

Surface Deterioration

The backwashing process used regularly to clean water filtration tanks is a naturally abrasive process which attacks the surface of the tanks, removing the traditional waterproofing coatings used to protect them. This in turn exposes the concrete to hydrostatic pressure, resulting in reinforcing steel corrosion and leaking.

Water Treatment Structures

- Raw Water Intake Structures

- Flocculation Basins

- Sedimentation Basins

- Water Filtration Tanks

- Reservoirs & Distribution Structures

Typical Concrete Problems

- Concrete Defects

- Cracks & Joint Leaks

- Surface Deterioration

- Chemical Attack

- Freeze/Thaw Damage

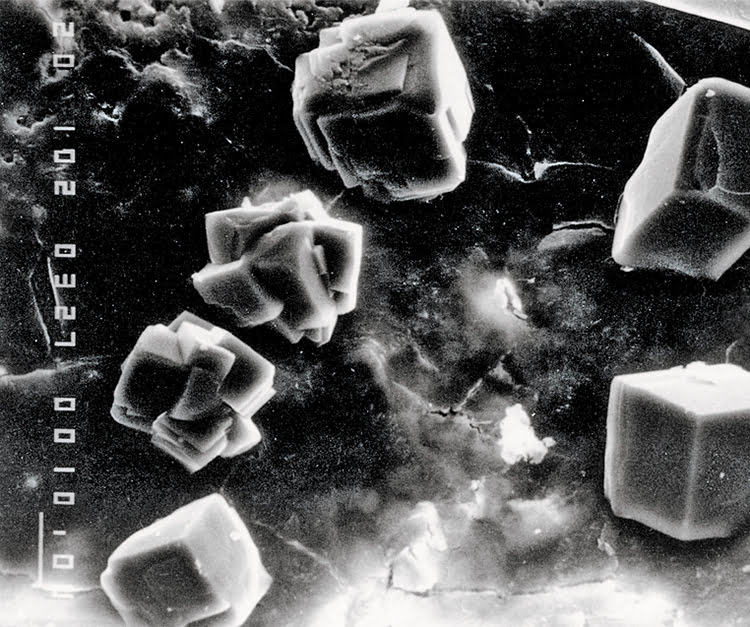

Xypex Crystalline Technology

Xypex products use the natural porosity of concrete and chemical diffusion to penetrate its pores and capillaries. Inside the concrete, Xypex chemicals react with the by-products of cement hydration to form a non-soluble crystalline structure deep within the substrate. In this condition, the concrete becomes impermeable, preventing the penetration of liquids and chemicals from any direction even under extreme hydrostatic pressure. The chemical resistant properties of the crystalline structure prevent the effects of attack by chemicals used in the treatment process.

The Xypex Advantage

Xypex Crystalline Technology works inside the concrete, thereby avoiding the problems typical of traditional barrier products.

- Resistant to chemical attack

- Not subject to the deterioration problems encountered by coatings

- Self-heals static cracks up to 0.5 mm (0.02 in)

- Permanent and reactivates whenever water is present

- May be applied on negative or positive side of concrete surface

- Non-toxic; approved for use with potable water

Proven Performance Worldwide

Comprehensive quality systems and standards along with thorough testing in the lab and the field have resulted in Xypex’s highly respected position in the concrete industry. Xypex has been extensively tested by independent testing laboratories in the U.S., Canada, Australia, Japan, Europe and other countries.

![]()

Xypex Admix for New Concrete Construction

Xypex Admix is the preferred choice for installing Xypex Crystalline Technology into new concrete structures for water treatment plants. Because Xypex Admix is blended into the mix at the time of batching, it becomes an integral part of the entire concrete matrix, reducing the potentially damaging effects of water penetration and chemical attack. Flexibility in application means Xypex Admix can be installed in pre-cast elements, cast-in-place structures and added to shotcrete concrete mixtures.

Xypex Admix Advantages

- Permanent integral waterproofing

- Enhances concrete durability

- Value engineering

- Non-toxic

- Non-combustible

- Resists damaging effects of water penetration and chemical attack

Discover the full potential

of Additive products.

Rehabilitation & Repair

Xypex’s coating systems and repair products enable municipalities, engineers and

contractors to economically and confidently rehabilitate deteriorating water treatment structures. Xypex Concentrate and Modified are applied as slurry coatings to the surface of the concrete. Unlike other materials that need a dry substrate, Xypex products require a moist surface – conditions typical of existing water treatment structures. Xypex Patch’n Plug, Concentrate Dry-Pac and Megamix products are specifically designed to permanently repair concrete defects such as honeycombs, static cracks and faulty cold or construction joints. These products are also effective at filling tie-holes and sealing around pipe penetrations.

Xypex Coating Advantages

- Doesn’t require a dry surface

- Apply to either side of the concrete

- Won’t puncture, blister or tear

- No costly surface priming or leveling

- Sealing, lapping or finishing is not required

- No need for protection during backfilling

- Permanent waterproofing

- Enhanced concrete durability

- Doesn’t contain VOCs

Other Accessory Products are also available.

SEE XYPEX PRODUCTS

Find the right product

for your project.

Mao Water Treatment Plant

Cardedeu Water Purifying Plant

Hanahan Water Treatment Plant – Clearwell #3

National Commission for Water

Showa Glove Factory

Bearspaw Water Treatment Facility

Svobodka Waterworks

Potable Water Tanks

Potable Water Tanks