Sustainability

Sustainability in Today's Construction:

A Continuous Commitment

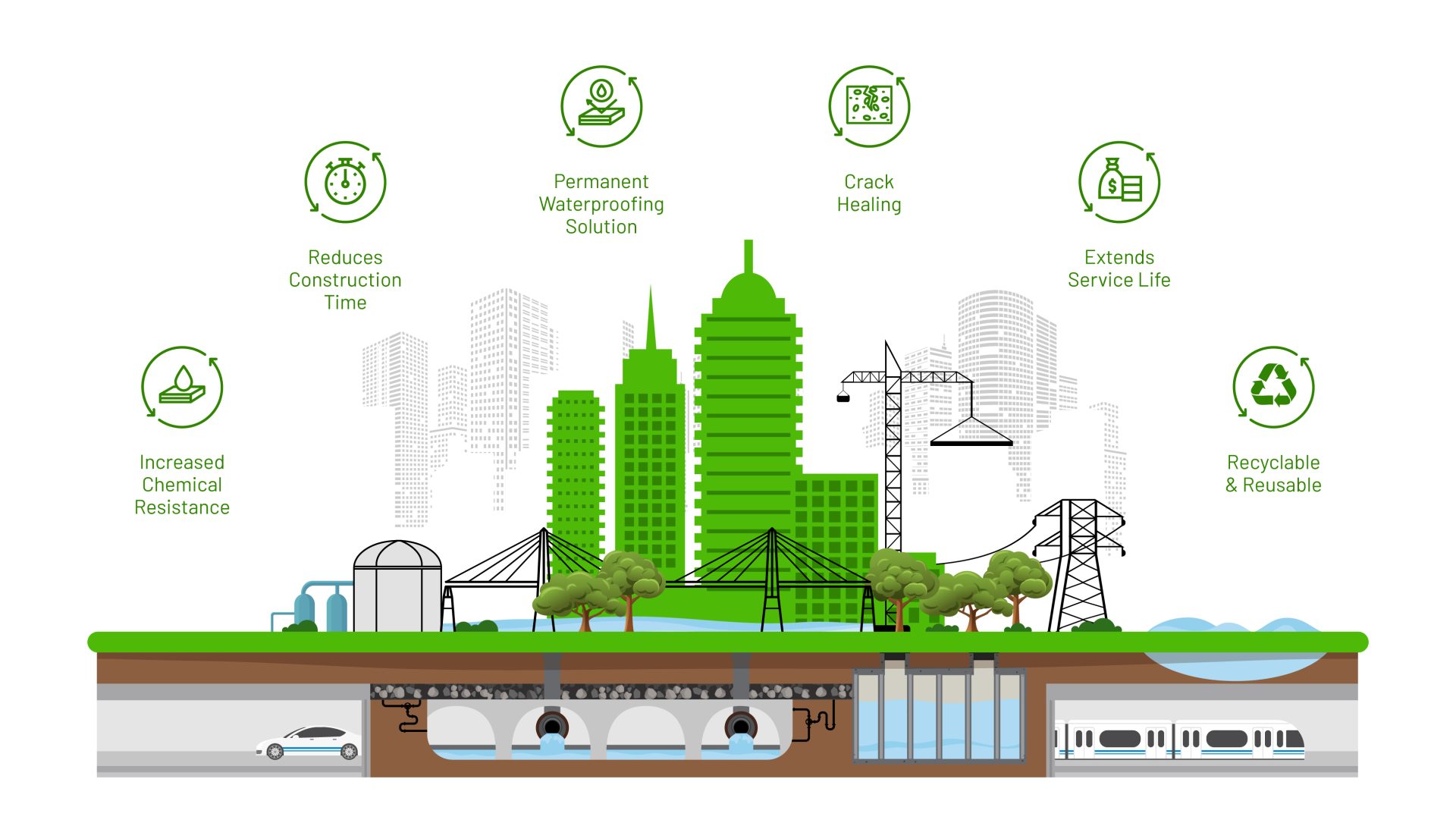

At Xypex, sustainability isn’t a new concept; it’s been our guiding principle since the company’s creation in 1969. In today’s context, sustainability means building and developing in a way that meets the needs of the present without compromising the ability of future generations to meet their own needs. Our crystalline technology epitomizes this approach, providing durable and permanent concrete waterproofing while enabling circular construction practices.

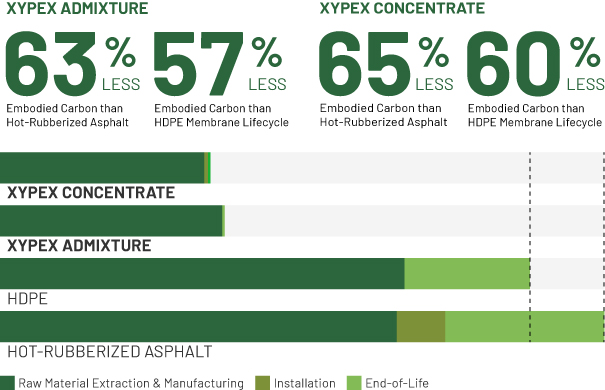

Central to our commitment is helping you reduce your project’s carbon footprint and attain your sustainability goals. Xypex technology has a 60% lower carbon footprint than traditional waterproofing membranes and coatings and contains no VOCs, minimizing environmental impacts. Xypex permanently waterproofs the concrete, resulting in an extended service life reducing the need to replace or repair the waterproofing during the life of the structure, resulting in a much lower lifecycle impact and cost.

Validated by Environmental Product Declarations (EPD) and Health Product Declarations (HPD), Xypex aligns with industry standards for efficiency and environmental responsibility, supporting LEED credits. We are dedicated to to a future where construction stands the test of time and promotes environmental health and resource efficiency.

Xypex Green Building Materials: A Detailed Look

Extended Service Life Reduces the Frequency of Repairs and Replacements

Xypex crystalline technology goes beyond traditional membranes or coating waterproofing methods. Our advanced formulations are engineered to significantly enhance the durability of concrete structures, typically tripling their service life.

This dedication to longevity reduces the frequency of repairs and replacements, substantially impacting the sustainability of construction projects. By extending the lifespan of structures, we significantly lower their overall environmental footprint.

Green Building Materials

Free from harmful volatile organic compounds (VOCs), Red List Chemicals and Forever Chemicals (PFAS).

Xypex products ensure safer, healthier environments for both builders and end-users.

Certifications and Standards: Building Trust with Xypex

A Testament to Quality and Sustainability

Environmental Product Declarations (EPD) and Health Product Declarations (HPD) validate our products; compliance with global green standards.

Xypex goes beyond the industry standard by producing “Cradle to Grave”, Type III, third-party validated EPDs, done in accordance with ISO 14025.

Contributing to LEED and Green Program-Certified Projects

Xypex plays a critical role in the achievement of LEED and other Green Building certifications. By incorporating Xypex products, architects and builders can secure valuable points in green building projects.