Bio-San

Xypex Bio-San is a uniquely designed admixture for integral, long-term protection of concrete in harsh sewage conditions with levels of H2S that cause microbial induced corrosion (MIC). Bio-San combines potent antimicrobial protection along with the unique crystalline technology of the Xypex Admix C-Series.

Bio-San contains bio-active mineral solids that become permanently fixed within the cement matrix impairing bio-film formation thus inhibiting the growth of acid causing sewer bacteria such as Thiobacillus due to concentrations of H2S. The unique Xypex Crystalline Technology creates a permanent structure throughout the pores and capillary tracts providing waterproofing and enhanced chemical protection including acid and sulphate resistance. Bio-San prevents microbial induced corrosion, stops infiltration/exfiltration of water, and provides acid and sulphate resistance, significantly extending the service life of concrete sewage collection systems and waste water infrastructure.

Xypex Admixtures now contain the latest in Xypex innovation, the Visual Detection System (VDS). It is designed to confirm the presence of Xypex Crystalline Waterproofing Admixture in hardened concrete. To learn more about VDS, click here: VDS

Advantages of Xypex

- Inhibits microbial induced corrosion

- Resists extreme hydrostatic pressure

- Resistant to aggressive chemicals (acids and sulphates)

- Can seal static hairline cracks up to 0.5 mm

- Becomes a permanent, integral part of the substrate

and cannot be punctured, damaged or lose adhesion - Does not contain any VOCs

- Less costly to apply than most other methods

- Added to the concrete at the time of batching and therefore

not subject to weather and surface moisture constraints - Contains Visual Detection System

Recommended for

- Manholes / Sewer Pipes

- Pump and Lift Stations

- Head Works

- Septic Tanks

- Digesters

- Clarifiers

- Industrial Structures

Packaging

Xypex Bio-San is packaged in 50 lb. (22.7 kg) pails. Contact the manufacturer for availability of customsized packaging to meet the requirements of your specific project.

Dosage Rate

1% by weight of total cementitious content.

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

Bio-San Specific Details

Xypex recommended procedures for waterproofing concrete tie holes in new construction where Xypex Bio-San C500 concrete has been used to protect against MICC attack.

Xypex recommended procedure for crack repairs performed on the sewage side of concrete elements that contain Xypex Bio-San C500.

Xypex recommended procedure for repair of standard, small or medium-large sized deficiencies in Xypex Bio-San C500 treated concrete.

General Resources

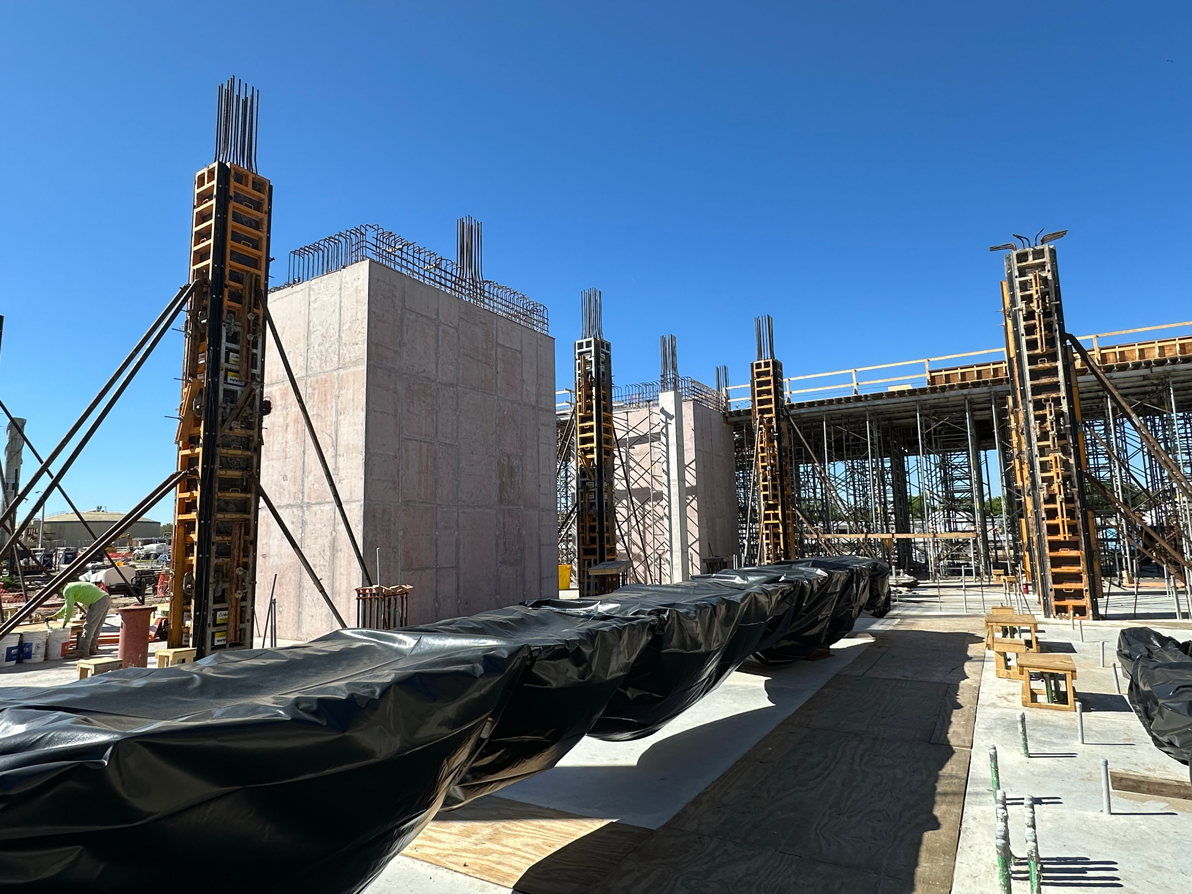

GBRA Stein Falls Water Reclamation Facility Expansion

The Guadalupe-Blanco River Authority (GBRA) expanded its Stein Falls Water Reclamation Facility to increase treatment capacity, improve solids management, and modernize chemical and electrical systems.

Pendleton-Clemson Regional Wastewater Treatment Plant Expansion

The Town of Pendleton undertook the expansion of the Pendleton-Clemson Regional Wastewater Treatment Plant to increase treatment capacity and improve long-term system reliability for the surrounding service area.

JEA Bio Solids Facility

The JEA Buckman Bio Solids Facility required durable concrete protection for new sludge holding tanks and the overhead structural slab exposed to aggressive wastewater conditions. These structures operate under continuous exposure to hydrogen sulphide and microbial activity that can lead to microbial induced corrosion. The project demanded a long-term solution capable of protecting concrete integrity without reliance on surface applied linings or membranes that require ongoing maintenance.

Saint-Isidore Wastewater Treatment Plant Upgrade

The Municipality of Saint-Isidore initiated an upgrade to its wastewater treatment facility to replace aging infrastructure and comply with updated environmental standards. The modernization involved the construction of new reinforced concrete structures, including a degritter building, a concrete treatment pond, and a pumping station.

Centre de traitement des boues – Etchemins

The project to renovate the regional septic tank sludge treatment center of the MRC des Etchemins, a facility located in Sainte-Germaine-Station, moved forward with the upgrade, which will also increase its treatment capacity. Xypex Bio-San was crucial in increasing durability, enhancing sustainability, and fortifying the plant against long-term wear.

Projects Using This Product

River Islands Sewage Pump Station

The River Island Sewage Pump Station faced two major challenges: as a sewage pump station the concrete required protection from microbial induced corrosion (MIC); and 9 m (30 ft) of the 12 m (40 ft) deep structure would be immersed in the surrounding water table. Xypex Bio-San admixture was chosen by the City of Lathrop as an alternative to the specified system.

South Lathrop Commons Center Sewage Pump Station

In order to protect the concrete structure from microbial induced corrosion and to achieve water tightness, Xypex Bio-San was added to the concrete mix at the Jensen Precast’s plant at the time of batching. The Bio-San contains antimicrobial crystalline technology which both kills the acid-producing microbes which proliferate in sewage structures as well as providing watertight, chemically resistant concrete with crack-healing properties.

Chatham Park WWTP

Due to the potentially high levels of H2S in the Bioreactor McKim & Creed, the engineers of record specified the use of a high build acid resistant coating to protect the concrete. Bowen Engineering proposed to the engineers Xypex Bio-San as an alternate to this coating because it contains Xypex’s antimicrobial crystalline technology.

Fairchance Sewer Line Extension

Liners or coatings would normally be used to perform this function. As these are expensive and time consuming to install, the engineers decided to specify the inclusion of Xypex Bio-San admixture in the pre-cast concrete.

Sonic Sanitary Lift Station & Manholes – Arizona WWTP

The Arizona Lift Station project involved a large cast-in-place wet well and drop/ discharge precast manholes. Xypex Bio-San was incorporated into all cast-in-place concrete and grout in direct or indirect contact with wastewater.

American Furniture Manholes

The design team was looking for corrosion protection for the manholes and chose Xypex Bio-San over the alternate antimicrobial admixture. Xypex Bio-San was chosen because it provides the precast sewage elements with protection against microbial induced corrosion and aggressive chemicals, as well as waterproofing and crack healing properties.