Megamix Series

Xypex Megamix I is a thin parge coat for the waterproofing and resurfacing of vertical masonry or concrete surfaces, as a cap coat for Xypex Concentrate, or as an architectural rendering. Megamix I is a unique blend of Portland cement, treated silica sand, fibers and proprietary chemicals. It is mixed with Xycrylic Admix to produce enhanced bond. Megamix I is applied by brush or trowel up to a thickness of 3/8 in. (10 mm).

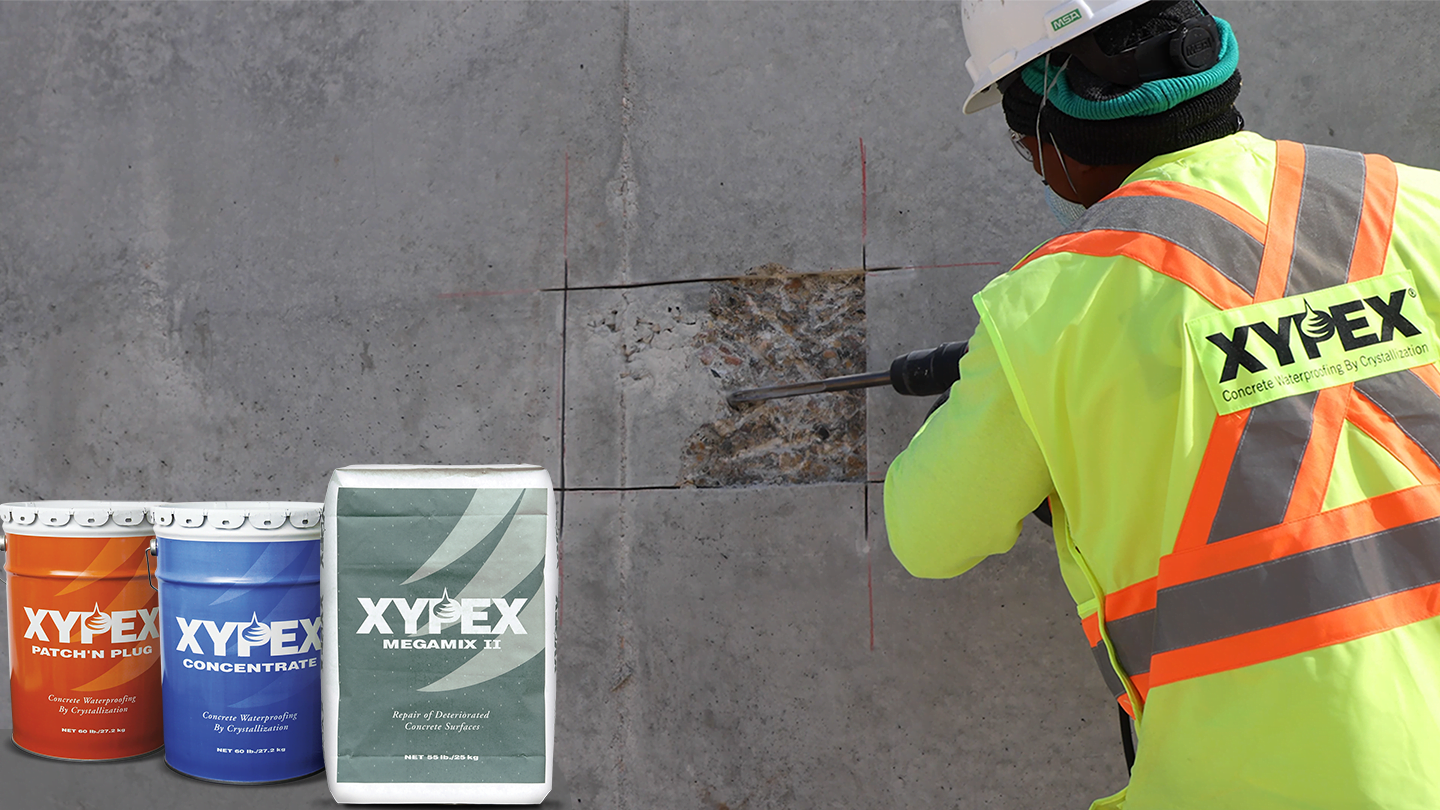

Xypex Megamix II is a thick repair mortar for the patching and resurfacing of deteriorated concrete. Megamix II has been specifically formulated to produce superior bond, low shrinkage, chemical durability and high strength. It is a one component mortar and can be either sprayed or trowel applied at a thickness of 3/8″ – 2″ (10 – 50 mm).

Xypex Megamix II with Bio-San is a resurfacing mortar specifically designed for the restoration of deteriorated concrete surfaces caused by microbial induced corrosion, abrasion/erosion and chemical attack. It is formulated for ease of application, superior bond, low shrinkage, high strength and resistance to microbial, acid and sulphate attack. Megamix II with Bio-San contains bioactive mineral solids which fix permanently within the repair mortar matrix impairing bio-film formation, thus limiting microbial induced corrosion of the repaired surface in sewer environments. It significantly extends the life of sewer and waste water infrastructure by inhibiting the growth of acid causing sewer bacteria such as Thiobacillus that cause MIC (microbial induced corrosion). In most applications, such as manhole resurfacing, Megamix II with Bio-San can be used to replace epoxy linings and calcium aluminate repair mortars.

Advantages of Xypex

MEGAMIX I

- Excellent adhesion and bond to concrete substrates

- Easy to apply

- Fiber reinforced

- Reduces surface absorption

- Provides good surface for painting or as a final finished surface

- Non-toxic / no VOCs

- NSF 61 certified

MEGAMIX II

- Excellent adhesion and bond to concrete substrates

- Low shrinkage, fiber reinforced

- Low chloride penetration

- Ready to use – just add water

- Vertical and overhead concrete repair; sprayable

- Non-toxic / no VOCs

- NSF 61 certified

MEGAMIX II WITH BIO-SAN

- Excellent adhesion and bond to concrete substrates

- Inhibits microbial induced corrosion

- Low shrinkage, fiber reinforced

- Resistant to acid attack

- Very resistant to severe sulphate exposure

- Highly resistant to chloride diffusion

- Ready to use – just add water

- Vertical and overhead concrete repair; sprayable

- Non-toxic / no VOCs

- CE certified meeting EN 1504-3

Recommended for

MEGAMIX I

- Waterproof coating for vertical concrete block surfaces and cast-in-place concrete walls

- A secondary or cap coat for Xypex Concentrate applications to porous masonry surfaces

- Lining for swimming pools, tunnels and tanks

MEGAMIX II

- Water Tanks and Reservoirs

- Sewage Treatment Plants

- Concrete Water and Sewer Pipes

- Manholes and Vaults

- Marine Structures

- Bridge Structures

- Tunnels and Parking Garages

MEGAMIX II WITH BIO-SAN

- Manholes / Sewer Pipes

- Pump and Lift Stations

- Head Works

- Septic Tanks

- Digesters

- Clarifiers

- Industrial Structures

Packaging

Megamix I is available in 60 lb. (27.2 kg) pails. Megamix II and Megamix II with Bio-San are available in 55 lb. (25 kg) bags or in customized packaging to meet your specific requirements

Coverage

Megamix I: At the recommended thickness of 1/8 in. (3.2 mm), one 60 lb. (27.2 kg) pail will cover 47.5 sq. ft. (4.4 m2 ). Megamix I may be applied as thin as 1/16 in. (1.6 mm) provided it is used as a cap coat over a coat of Xypex Concentrate. Megamix II and Megamix II with Bio-San: At 1/2 in. (12.5 mm) thickness, each 55 lb. (25 kg) bag will cover 11.3 sq. ft. (1.05 m2).

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

Megamix Application Details

General Resources

TE MAXSON Trickling Filters 1-4

The T.E. Maxson Facility, which began operations in 1975, plays a crucial role in Memphis's wastewater treatment infrastructure. The facility treats an average of 70 million gallons of wastewater per day and has the capacity to handle peak flows of up to 120 million gallons during storm events. It serves over 230,000 residents of Memphis, part of the city's population of more than 650,000.

Ikaalisten Vesitorni Water Tower Rehabilitation

The rehabilitation and waterproofing project for the Ikaalisten Vesitorni Water Tower in Finland required materials certified for potable water. Its shape also presented unique challenges making it difficult to install scaffolding and access both the inner and outer basins, so traditional waterproofing methods were not suitable applications.

Holland Township Community Pool

The Holland Township Community Pool in Milford, NJ, has existed since the 1950s. However, deterioration over time has resulted in severe cracks in the concrete. The cracks have compromised the pool’s ability to maintain a watertight structure, necessitating annual repairs.

Wastewater Clarifier Repair advancing City Green Initiatives

The city of Hollywood, Florida, is steadfast in its commitment to sustainability, exemplified by initiatives such as maintaining and upgrading its wastewater treatment infrastructure with sustainable solutions. At a groundbreaking ceremony to announce a $112 million investment for a new pump station, complete with deep injection and monitoring wells, Mayor Josh Levy emphasized the significance of this work, stating that it "demonstrates the city's dedication to the environment and other positive green initiatives."

Projects Using This Product

Largo Wastewater Treatment Plant

The concrete BNR trains were in need of the highest level of restoration, having been exposed to physical and chemical attack throughout 50 years of service. Xypex Megamix II with Bio-San, a one-step repair mortar that provides both crystalline waterproofing technology and a mineral-based antimicrobial that kills acid-generating bacteria.

Citywide Printing

The print shop and equipment is located in a business district not far from the Des Plaines River designated as a flood zone. The bottom 4 feet of exterior walls was treated with one-half inch of Xypex Megamix II on the outside.

City of Alameda Manhole Rehabilitation

Twelve of the manholes were brick and mortar construction that required rehabilitation from deterioration due to the corrosive H2S environment to which they had been exposed. While the brick showed only minor deterioration the Portland cement based mortar joints were severely corroded. These 12 manholes were rehabilitated using Megamix II with Bio-San as an over coating layer to repoint the joints as well as coat the entire surface.

Singapore Marina Barrage

More than 7,000 kg of Xypex Megamix II were used to shape and protect the new fins of the Barrage gates. Xypex Megamix II was the only product available in the market that could applied to the very fine (1 mm) tolerances specified for the barrage, whilst its superior ability to withstand the harsh chemical and mechanical marine environment conditions contribute incrementally to the durability of the fins of the barrage.

Milner-Gooding Canal

The first step in the restoration required extensive high pressure water blasting to remove the decades of lime deposits. Once these were removed and the surfaces were clean, Xypex Megamix II was used to patch badly deteriorated areas before a spray coat application of Xypex Concentrate.

Murray Irrigation

Xypex Megamix II was chosen as the preferred product to meet the engineer’s requirements for a repair render for deteriorated concrete surfaces applied at a rate of 20 kg/m2. As opposed to competitors’ high strength repair mortars, Xypex Megamix II contains Xypex’s unique crystalline technology, has high strength yet low shrinkage, and adheres excellently to damp concrete.