Why Xypex for Industrial Structures

Meeting the Challenge

Protecting Industrial Structures

Industrial concrete structures are constantly exposed to hydrostatic pressure, sulphates, chlorides, and other aggressive chemicals. Without proper protection, the structural integrity of the concrete is soon compromised, leading to expensive remediation efforts and a shortened life span. Once the moisture and chlorides have reached the reinforcing steel, an expansive oxidation process begins to take place causing the formation of cracks and spalling in the concrete. When cracking takes place and is combined with weathering effects such as freeze/thaw damage or accelerated corrosion in hot weather climates, this deterioration takes place at a faster pace.

With over 50 years of experience in 90 countries around the world, Xypex Crystalline Technology has been used in a variety of industries to waterproof, protect, repair and enhance the durability of concrete. In this challenging environment, Xypex is a highly respected partner in extending the service life of industrial structures.

Xypex products play a key role in the waterproofing and protection of concrete against water penetration due to hydrostatic pressure, and aggressive chemical attack – problems typically associated with the reduced service life of concrete industrial structures.

Chemical Attack

Industrial concrete structures are subject to attack from a variety of chemicals whether they be acidic or alkaline, organic or inorganic, man-made or natural. Amongst the many chemicals which attack concrete are acids (sulphuric, formic, lactic, acetic, carbonic, acid mine drainage), chlorides, sulphates, nitrates, and petrochemicals. Concrete may also be damaged during the manufacturing or waste treatment processes. The diffusion of these chemicals through porous concrete can cause problems such as corrosion of the reinforcing steel, cracking, and spalling of the concrete.

Ground Water

A priority in the waterproofing of concrete industrial structures is the prevention of water ingress due to hydrostatic pressure from the surrounding water table. Both on-grade and below grade structures must be protected against water damage and corrosion of the reinforcing steel. The nature of concrete and the problems associated with placement and consolidation means having to deal with permeability issues permitting the penetration of water into the substrate and through to the reinforcing steel. With the presence of oxygen this can initiate corrosion.

Wastewater Treatment

Industrial wastewater can contain everything from sediments to hormones to acids and is often damaging to the concrete structures involved in its treatment. Whether it is the removal of solids and sediment, oil and grease, or other chemicals, concrete used in wastewater treatment is exposed to a number of harsh elements that greatly increase the probability of cracking, spalling and corrosion. Concrete exposed to industrial wastewater may be subject to Microbial Induced Corrosion as a result of the production of Hydrogen Sulphide. Additionally, solids and sediment may damage the concrete through abrasion.

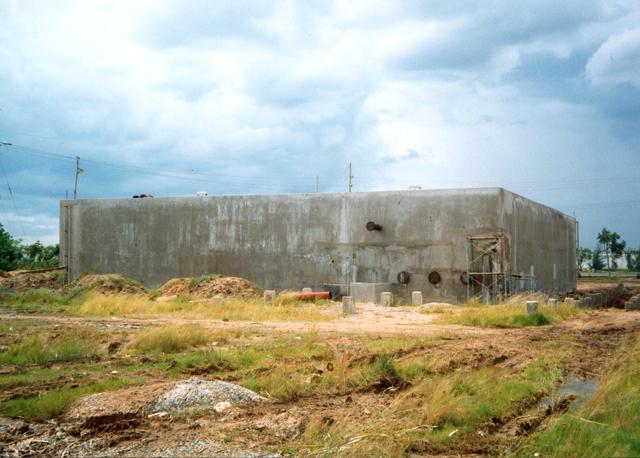

Containment

Concrete in industry is often used in a variety of primary and secondary containment settings, in which tanks, channels, water treatment structures, cooling tower basins and additional supporting structures must be protected from water ingress due to hydrostatic pressure, and chemical attack. The protection of the concrete is important for several reasons: Not only must the concrete be protected in order to maintain its structural integrity and to avoid costly rehabilitation, but it must also protect the surrounding environment from leaks. The constant loss of any liquid also causes significant increases in the operating cost of industrial facilities.

Additional Problems: Cracking, Carbonation, Freeze/Thaw, Alkali Aggregate Reaction, Surface Deterioration (Abrasion)

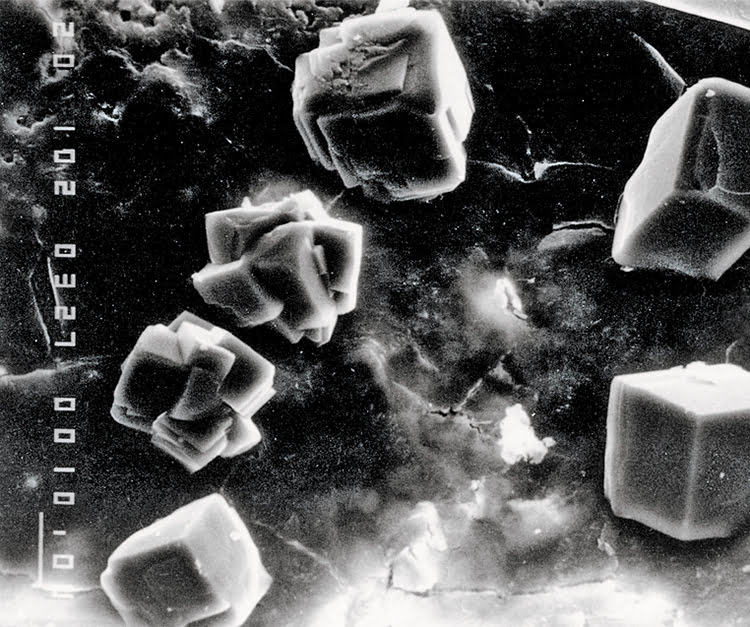

Xypex Crystalline Technology

Xypex products use the natural porosity of concrete and chemical diffusion to penetrate its pores and capillaries. Inside the concrete, Xypex chemicals react with un-hydrated cement particles and the by-products of cement hydration to form a non-soluble crystalline structure deep within the substrate. In this condition, the concrete becomes impermeable, preventing the penetration of liquids and chemicals from any direction even under extreme hydrostatic pressure. The chemical resistant properties of the crystalline structure will mitigate the attack of chlorides, sulfates and other aggressive chemicals. In prolonging the durability of concrete, Xypex has also proven to be effective against the effects of carbonation and Alkali Aggregate Reaction as well as having the ability to self-heal static cracks up to 0.5 mm (0.02 in). Xypex also improves the freeze-thaw durability of concrete.

The Xypex Advantage

Xypex Crystalline Technology works inside the concrete, thereby avoiding the problems typical of traditional barrier products.

- Permanent and reactivates whenever water is present

- May be applied on negative or positive side of concrete surface

- Self-heals static cracks up to 0.5 mm (0.02 in)

- Not subject to deterioration problems encountered by surface coatings and membranes

- Requires no additional protection as with preformed membranes

- Resistant to chemical attack

Proven Performance Worldwide

Comprehensive quality systems and standards along with thorough testing in the lab and the field have resulted in Xypex’s highly respected position in the concrete industry. Xypex has been extensively tested by independent testing laboratories in the U.S., Canada, Australia, Japan, Europe and other countries.

Xypex Admix for New Concrete Construction

Xypex Admix is the preferred choice for installing Xypex Crystalline Technology into most new concrete industrial structures. Because Xypex Admix is blended into the mix at the time of batching, it becomes an integral part of the entire concrete matrix, thus reducing the potentially damaging effects of water penetration, chloride and sulfate attack, carbonation, Alkali Aggregate Reaction and other aggressive chemicals. The addition of Xypex Admix to concrete is a highly effective method of enhancing the durability of concrete structures.

Xypex Admix Advantages

- Permanent integral waterproofing

- Enhances concrete durability

- Value engineering

- Non-toxic

- Non-combustible

- Resists damaging effects of water penetration and chemical attack

Discover the full potential

of Additive products.

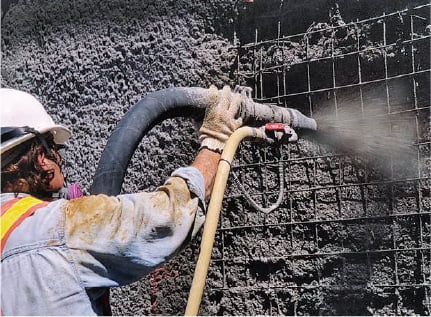

Rehabilitation & Repair

Xypex’s coating systems and repair products enable owners, engineers and contractors to economically and confidently repair structures that have been damaged by water ingress due to hydrostatic pressure, chloride and sulphate attack, carbonation, Alkali Aggregate Reaction, or exposure to aggressive chemicals. Xypex Concentrate and Modified are applied as slurry coatings to the surface of the concrete. Unlike other materials that need a dry substrate, Xypex products require a moist surface. This type of environment is conducive to the Xypex Crystalline process. Xypex Patch’n Plug, Concentrate Dry-Pac and Megamix products are specifically designed to permanently repair concrete defects such as static cracks and faulty cold or construction joints. Xypex Megamix returns structural integrity to severely damaged concrete, whilst maintaining the same protective properties of Xypex-treated concrete.

Xypex Coating Advantages

- Doesn’t require a dry surface

- Apply to either side of the concrete

- Won’t puncture, blister or tear

- No costly surface priming or leveling

- Sealing, lapping or finishing is not required

- No need for protection during backfilling

- Permanent waterproofing

- Enhanced concrete durability

- Doesn’t contain VOCs

- Non-toxic and non-combustible

- Can be applied safely in confined spaces

Other Accessory Products are also available.

SEE XYPEX PRODUCTS

Find the right product

for your project.

Canadian Crude Separators

Sempra Energy Natural Gas Terminal

Duracell Battery Warehouse

Repsol Fuel Station

Maple Leaf Foods Rothsay Bio Filter

Sakosa Industries - Yarn and Textile Plant

Subaru-Isuzu Automotive Plant

Tan Thuan Export Processing Plant

Heuston Railway Station Tank Farm