Admix C-Series

Xypex Admixtures are added to the concrete at the time of batching, making it easy to install, and unlike other waterproofing methods, require less trades on site and shorten the time required for installation. The Admix C-Series has been specially formulated to meet varying project and temperature conditions.

Admix C-500/C-500 NF is formulated to have minimal or no effect on setting time. Admix C-1000/C-1000 NF is formulated for concrete mix designs where a normal or mildly delayed set is desired. Admix C-2000/C-2000 NF is designed for warmer climates and projects where a slower hydration rate is typically required. Admix C-500 NF Red and Admix C-1000 Red contains a red oxide pigment as a quality assurance measure for precasters.

Xypex Admixtures now contain the latest in Xypex innovation, the Visual Detection System (VDS). It is designed to confirm the presence of Xypex Crystalline Waterproofing Admixture in hardened concrete. To learn more about VDS, click here: VDS

Advantages of Xypex

- Integral part of concrete matrix

- Hydrostatic pressure

- Crack healing

- Chemical resistance

- Breathable

- Non-toxic

- No VOCs

- Is Permanent solution requiring no further maintenance

- Economical

- Shortens construction scheduled

- Extends service life on concrete

- Contains Visual Detection System

Recommended for

- Reservoirs and Water Holding Structures

- Water and Wastewater Treatment Plants

- Manholes and Pump Stations

- Precast Concrete

- Foundations

- Basements and Underground Parking Structures

- Tunnels and Subway Systems

- Secondary Containment

- Water Marine Structures

- Swimming Pools

*Refer to our Product Data for specifics

Packaging

Xypex Admix C-Series is packaged in convenient sizes of various types of packaging, including repulpable paper bags and soluble bags. Contact your local Xypex Technical Services Representative or dealer for details and availability.

Dosage Rate

Dosage will vary. Please refer to product data of the Admix product for specific dosage details.

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is two years when stored under proper conditions.

Admix Application Details

General Resources

Imbanaco Clinic Basement Waterproofing

During the construction of Clínica Imbanaco, one of Cali's largest hospitals and a recipient of the prestigious ECRI Health Technology Excellence Award, an effective waterproofing solution was essential for the multi-level basement, located in an area with a high water table.

Kalaranna District 3. Stage

Kalaranna District is a premium, modern residential development located on a prime six-hectare seaside site in Tallinn. The district features 12 residential buildings that integrate upscale restaurants, boutiques, and commercial spaces centered around a vibrant public square.

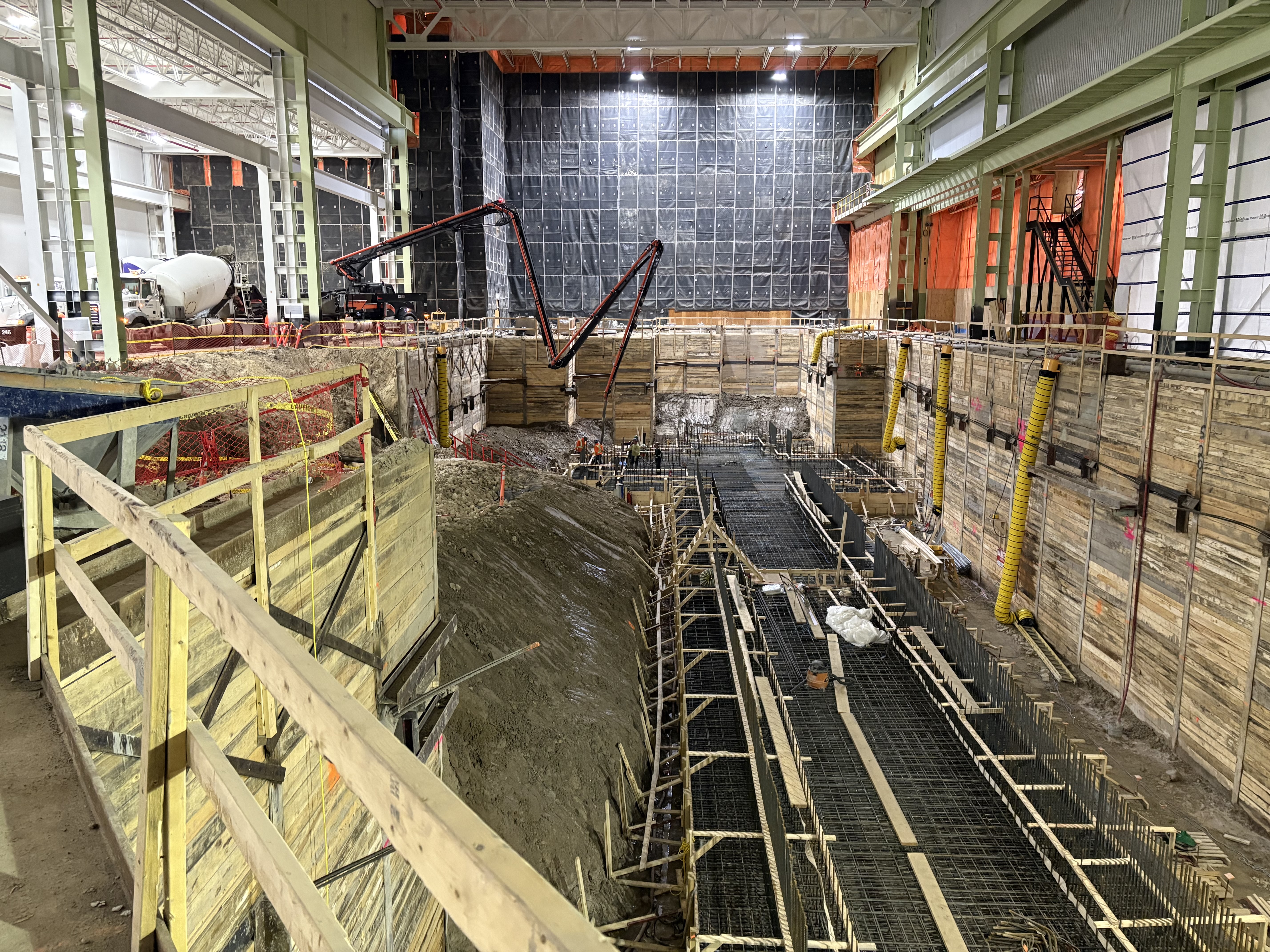

KTH Shelburne Facilities Expansion

KTH Shelburne Manufacturing Inc., a key supplier of automotive frame components, began a major expansion of its Ontario manufacturing campus to support new production lines and install a 400-ton stamping press.

F.lli Giacomel - New AUDI Dealership

The project involved constructing a new flagship AUDI dealership in Milan, which required deep excavation of approximately ~8m below grade. The scope included the foundation slab, below-grade reinforced concrete (RC) perimeter walls, industrial floors, a stormwater storage tank, and a fire-fighting water tank.

PACCAR Cab Storage Facility Expansion

PACCAR, a leading manufacturer of heavy-duty trucks, expanded its Sainte-Thérèse facility to increase storage capacity for finished cab units. The new addition required durable, watertight concrete construction to protect sensitive industrial components and maintain efficient operations throughout the year.

Projects Using This Product

Amos Rex Art Museum

Budapest Pedestrian Tunnel

The key challenges in building this pedestrian tunnel were the high water table created by the close proximity of the Danube River and addressing the need to prevent interruption of traffic flow on the street between the buildings. The street is both a major thoroughfare for cars as well as a street car line. The tunnel needed to be water tight to create a comfortable pedestrian space and the traffic needed to be maintained throughout the construction phase.

Rod el Farag Axis Bridge

More than one million cubic meters of concrete was used to build the bridge, which was used in the bridge decking, girders, and six 92 m (302 ft) tall concrete towers that support 160 steel support cables. One of the key challenges for the bridge designers was how to adequately protect the critical concrete structures from the effects of air pollution and the moist riverine environment.

Sorek Desalination Plant

After thorough investigation, the project design team chose to include 1.5% of Xypex C-500 NF Admixture in the concrete mix to both heal cracks as well as improve the overall chloride durability of the pipe. As the pipe was jacked into place visible leaking was seen in the pipe sections. All visible leakage was seen to heal and the project became so impressed with Xypex’s crack healing ability that the use of the Xypex Admix was extended in the project to include most of the water processing and holding structures as well as the pipe.

Taylor Shellfish Processing Facility

Blacklick Creek Sanitary Interceptor Sewer

To further protect the concrete tunnel from the harsh conditions expected during its projected 100-year lifespan and to ensure watertight operation, the high performance concrete mix was enhanced with Xypex Admix C-500.

Panama Canal – Chamber Walls & Gatun Lock Culverts

The aggressive marine environment surrounding the over 80-year-old Panama Canal had caused substantial deterioration of the canal’s concrete. Xypex Admix C-2000 was used in the concrete repair mortar to rehabilitate the walls of the gatun lock chambers and conduits.