For over 50 years, Xypex has been trusted by design professionals, engineers and contractors to:

- Resist hydrostatic pressure

- Permanently seal hairline cracks

- Reactivate and self-heal whenever water is present

- Provide chemical resistance

- Reduce short and long-term costs

- Save on construction time and on site labour

- Extend the service life of concrete

Products

Admixtures, Surface Applied Coatings and Concrete Repair Products

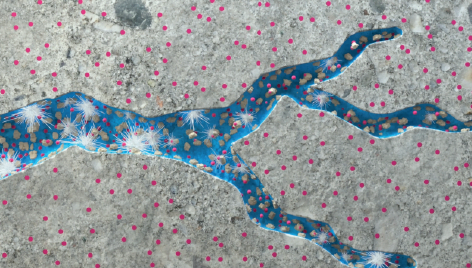

Our innovative approach to concrete waterproofing is the basis of all Xypex admixtures, surface-applied coatings and dry-shakes that waterproof concrete structures, repair concrete cracks and protect against aggressive chemical attack.

Feature Projects

Ramses II Statue at the Grand Egyptian Museum

In 2018, the Grand Egyptian Museum (GEM) in Giza undertook the relocation of the 83-ton, 3,200-year-old statue of Ramses II—a monumental piece of art and history. The primary objective was to preserve this unique historical artifact and provide a more suitable environment for its display and appreciation.

International Nile Club, Celebration Hall

The International Nile Club, situated along the Blue Nile river in Khartoum, Sudan, specified bituminous membrane sheets and polyethylene sheets for waterproofing basements and other areas of the structure. However, this waterproofing solution failed within a year of application. Xypex products were selected to waterproof the areas where traditional waterproofing could not.

Churchill Offices

The construction of the new Churchill Square office project in Prague consists of two modern AAA-Class administrative buildings, aimed to create a contemporary and functional space while seamlessly integrating with the historic surroundings. Jakub Cigler Architects designed the project to achieve LEED GOLD certification, demonstrating a commitment to sustainability and employee well-being.

Albaraka Parkings & Gardens Waterproofing

The Albaraka Bank Tower, owned by the prominent Albaraka Bank-Sudan, is situated near the Blue Nile River in Khartoum, Sudan. This project encountered a critical challenge with high groundwater pressure, posing a threat of water ingress to the underground parking and surrounding garden areas. To address this challenge and ensure a permanent and reliable waterproofing solution, engineers chose the unique Xypex Crystalline Technology.

Bridge, Prague Castle

Completed in 1995, the restoration of the Bridge at Prague Castle in Prague, Czech Republic, focused on finding a solution to address the waterproofing challenges and seepage into the masonry of the bridge structure

Pinheiros Sewage Pumping Station

Xypex Bio-San was selected due to its ability to permanently waterproof the concrete and increase the structure’s resistance to sulfates and sulfuric acid attacks while preventing the growth of the bacteria that causes MIC.

Michigan Avenue Harrison Road Sewer Improvement

Xypex Bio-San is a uniquely designed admixture for integral, long-term protection of concrete in harsh sewage conditions with levels of H2S that cause microbial induced corrosion (MIC). Bio-San combines potent antimicrobial protection along with the unique crystalline technology of the Xypex Admix C-Series.

West Gate Tunnel

Engineers were concerned about potential adverse effects of carbonation from vehicle emissions on the concrete infrastructure for the West Gate Tunnel project. The general contractor conducted tests on concrete treated with Xypex Admix C-500 and found that the Xypex-treated concrete reported a carbonation effect depth of 0 mm. As a result it was decided to add Xypex Admix C-500 in the concrete for the exhaust ducts to permanently waterproof, enhance durability, and provide resistance to carbonation throughout the concrete’s lifespan.

Glass City Metropark

Situated alongside the Maumee River in Toledo,

Ohio, the utility vault’s location presented the

threat of water infiltration, potentially leading to

damage to the electrical equipment and compromising

the structure’s overall functionality and safety.