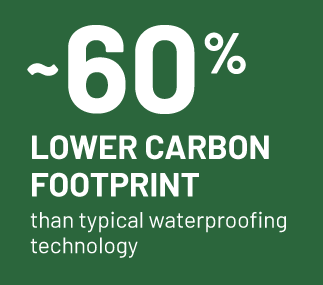

Reduced Carbon Footprint

Xypex CO2 Reduction Report: Paving the Way for Greener

Construction

Reduce your carbon footprint with Xypex products

We invite industry professionals to explore our CO2 reduction report and see how Xypex innovative technology can contribute to your sustainability goals.

Play video