Dam & Irrigation

Preserving Structural Integrity of Dams

The long-term structural integrity of dams and irrigation systems depends on keeping moisture from contacting the steel reinforcement. Inadequate waterproofing, cracks, failing joints, biochemical attacks, alkali aggregate reaction and abrasion are problems often found in this challenging environment.

Deteriorating concrete can lead to water loss, reduction in water flow and expensive unplanned maintenance. Failing or compromised dams and irrigation systems can even threaten public safety and environmental quality, so it is critical to protect and maintain them. Whether specified for new construction, or used for repairing and rehabilitating dams and irrigation systems, Xypex Crystalline Technology blocks water ingress into the structure and extends the life of these critical structures.

Find Projects

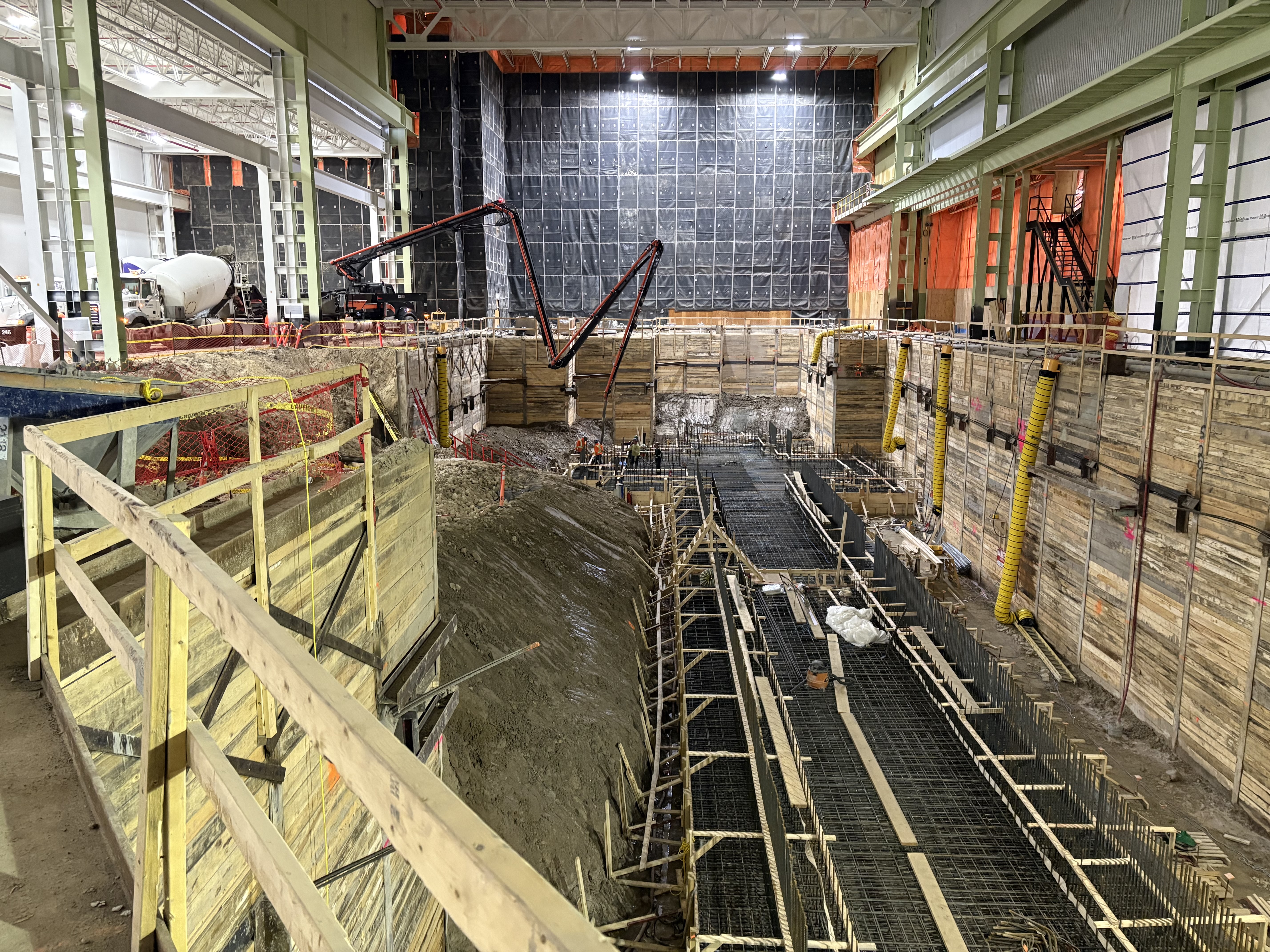

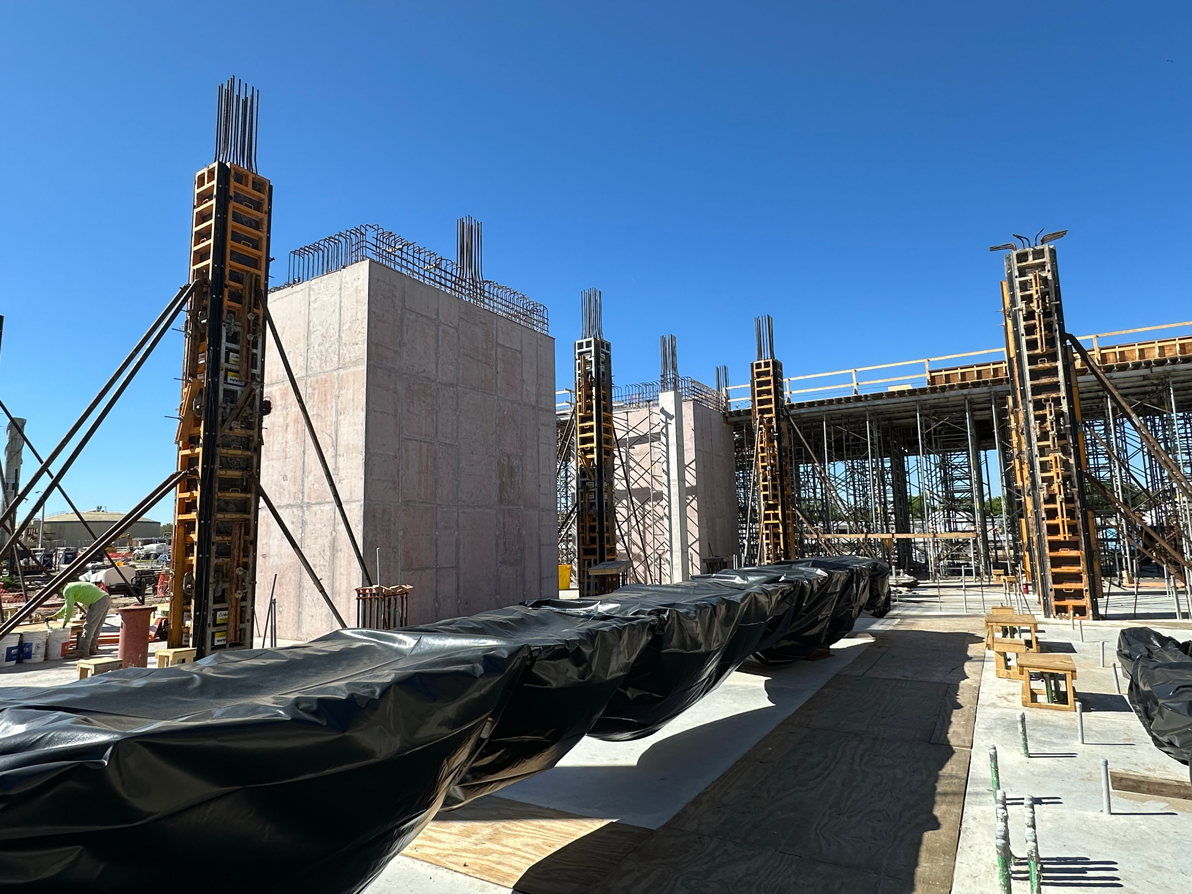

KTH Shelburne Facilities Expansion

KTH Shelburne Manufacturing Inc., a key supplier of automotive frame components, began a major expansion of its Ontario manufacturing campus to support new production lines and install a 400-ton stamping press.

GBRA Stein Falls Water Reclamation Facility Expansion

The Guadalupe-Blanco River Authority (GBRA) expanded its Stein Falls Water Reclamation Facility to increase treatment capacity, improve solids management, and modernize chemical and electrical systems.

Pendleton-Clemson Regional Wastewater Treatment Plant Expansion

The Town of Pendleton undertook the expansion of the Pendleton-Clemson Regional Wastewater Treatment Plant to increase treatment capacity and improve long-term system reliability for the surrounding service area.

F.lli Giacomel - New AUDI Dealership

The project involved constructing a new flagship AUDI dealership in Milan, which required deep excavation of approximately ~8m below grade. The scope included the foundation slab, below-grade reinforced concrete (RC) perimeter walls, industrial floors, a stormwater storage tank, and a fire-fighting water tank.

JEA Bio Solids Facility

The JEA Buckman Bio Solids Facility required durable concrete protection for new sludge holding tanks and the overhead structural slab exposed to aggressive wastewater conditions. These structures operate under continuous exposure to hydrogen sulphide and microbial activity that can lead to microbial induced corrosion. The project demanded a long-term solution capable of protecting concrete integrity without reliance on surface applied linings or membranes that require ongoing maintenance.