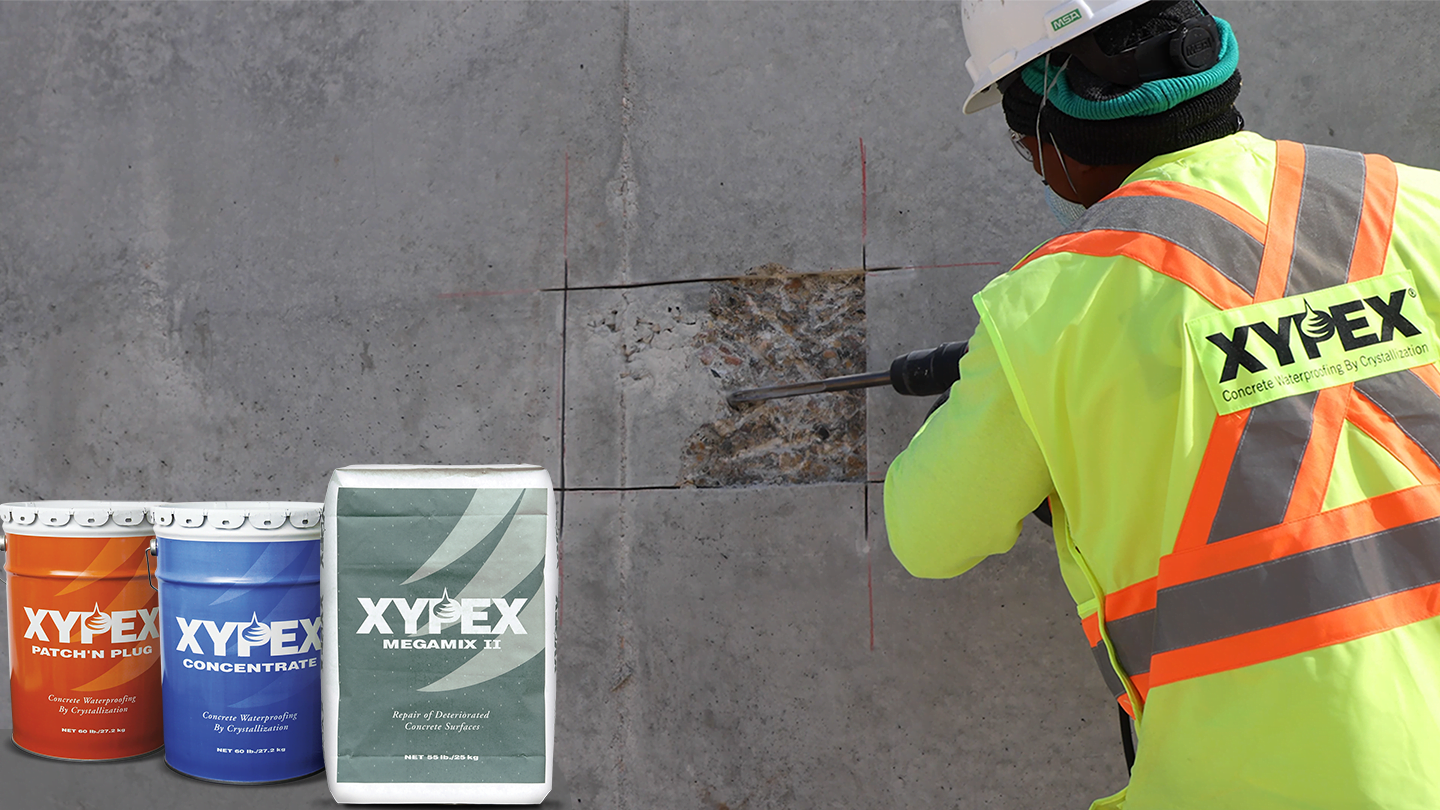

Concentrate

When mixed with water, this light grey powder is applied as a cementitious slurry coat to above-grade or below-grade concrete, either as a single coat or as the first of a two-coat application. Xypex Concentrate is also mixed in Dry-Pac form for sealing strips at construction joints, or for the repairing of cracks, faulty construction joints and honeycomb.

Advantages of Xypex

- Becomes an integral part of the substrate

- Resists extreme hydrostatic pressure

- Can seal static hairline cracks up to 0.5 mm

- Highly resistant to aggressive chemicals

- Can be applied to the positive or the negative side of

the concrete surface - Does not require a dry surface

- Non-toxic / no VOCs

- Is Permanent solution requiring no further maintenance

- Less costly to apply than most other methods

- Extends the service life of concrete

- No costly surface priming or leveling prior to application

- Does not require sealing, lapping and finishing of seams at

corners, edges or between membranes - Does not require protection during backfilling or during

placement of steel, wire mesh or other materials - Cannot puncture, tear or come apart at the seams

- Allows concrete to breathe

- Available in white for enhanced illumination

Recommended for

- Reservoirs

- Sewage and Water Treatment Plants

- Secondary Containment Structures

- Tunnels and Subway Systems

- Underground Vaults

- Foundations

- Parking Structures

- Swimming Pools

- Precast Components

Packaging

Xypex Concentrate is available in 20 lb. (9.1 kg) pails, 60 lb. (27.2 kg) pails and 50 lb. (22.7 kg) bags.

Coverage

For normal surface conditions, the coverage rate for each Xypex coat is 6 – 7.2 sq. ft./lb. (1.25 – 1.5 lb./sq. yd. or 0.65 – 0.8 kg/m2).

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

Coating Application - Method Statements

Xypex recommended installation procedures and general directions for waterproofing of concrete using Xypex Concentrate and Modified coatings.

Xypex recommended procedures for the repair of leaks and for the general waterproofing of below grade concrete structures performed on the negative side/inside of the structure.

Xypex recommended procedures for waterproofing CMU and concrete block structures from the positive or negative side.

Xypex recommended procedures to allow a rapid return to service of Xypex coated water holding structures (3 - 4 days from the start of material applications).

Xypex recommended procedures for application of thinset, plaster, stucco, cement parges, etc. onto Xypex Coatings.

Xypex recommended procedures for use of Xypex Coatings to waterproof dry mixed shotcrete (gunite) placed pools, fountains, etc that will receive tile, pool plaster or other additional overlaying finishes.

Xypex recommended Estimating Table is a guide only. Actual usage may vary according to the project.

General Resources

Address East Compound

For the Address East Compound project in New Cairo, Egypt, owned by Dorra Group, Shield for Specialized Constructions executed the waterproofing, using specifications and materials supplied by Beton, the Xypex agent in Egypt. The project utilized Xypex Concentrate for its critical waterproofing needs, including roofs, foundations, swimming pools, and water features.

Flensburg Navy Barrack Conversion

In the picturesque northernmost city of Germany, Flensburg, an ambitious project was undertaken to transform a section of an old German navy base into a new focal point for tourism, leveraging its stunning views of the Baltic Sea harbor and the quaint old town center.

Grain Silos

To waterproof and safeguard new grain silos in Behira, Smouha, and Bani Mazar, Elmenya, contractors applied Xypex Admix C 1000 NF to the horizontal slabs and used Xypex Concentrate for wall repairs. This approach was specifically designed to shield the structures from up to 8 meters of hydrostatic pressure, thereby enhancing their durability and waterproofing capabilities. The use of Xypex products in this project markedly increased the concrete's durability and the silos' overall longevity, ensuring they remain resilient against environmental pressures.

Biogas Plant Anaerobic Digestors

The Mramorak biogas plant in Serbia, operational since December 2019, represents a pivotal advancement in renewable energy technologies, specifically in converting organic waste into biogas. This project underscores the importance of selecting construction materials that can withstand the harsh conditions of anaerobic digestion—a process where microorganisms decompose organic matter without oxygen, producing biogas but also creating a highly corrosive environment for conventional concrete.

Holland Township Community Pool

The Holland Township Community Pool in Milford, NJ, has existed since the 1950s. However, deterioration over time has resulted in severe cracks in the concrete. The cracks have compromised the pool’s ability to maintain a watertight structure, necessitating annual repairs.

Projects Using This Product

Setia Spice Convention Centre

Given the environmental circumstances of the location, including a high water table, elevated levels of chlorides, sulphates and carbonating gasses, Xypex waterproofing technology was selected and specified for this project because, unlike other concrete waterproofing systems, Xypex offered permanent and enduring concrete waterproofing and protection, with cost savings accruing from reduced initial construction time as well as future concrete maintenance costs.

Gateway Arch Expansion

The gleaming stainless steel Gateway Arch is the centerpiece of the Gateway Arch National Park and a popular attraction. A plan was developed to dramatically expand and redesign the landscaping and facilities around the base of the Gateway Arch. Waterproofing of all renovated spaces and new facilities was a critical concern.

Canal do Sertão - Hinterland Water Channel

Xypex Crystalline Technology was introduced to the project as a means to solve a specific problem in the early stages of construction. As a result of its performance it became an important component of the whole project to solve the waterproofing challenges. The combined efforts of the federal government, the design team and the contractors together with technical assistance from Xypex distributor MC Bauchemie, enabled the timely delivery of these stages of this highly important project for the Sertão Nordestino region of Brazil.

National Centre of Infectious Diseases

Xypex’s crystalline system for concrete waterproofing and durability was proposed, approved, and accepted to provide protection to the four levels of underground substructure (basement base slabs and perimeters) and three underground pedestrian/vehicular underpass links.

Picayune Strand Restoration Project

The three pumping stations—Merritt, Faka Union, and Miller—were completed in early 2018 and are being used to restore the flow of freshwater over land (known as sheet flow) and maintain pre-existing flood protection. Soon after completion, hydrostatic pressure caused the Merritt pump rooms, located 20 feet (6 m) below grade, to fill with water.

Zuidhorn Rail Bridge

The use of Xypex Concentrate to protect the new railway bridge over the Van Starkenborgh Canal not only helped keep the project on schedule, but provided a significant cost savings over the epoxy coating that ProRail normally uses on such projects.