Gamma Cure

Xypex Gamma Cure is a curing agent designed to be used in conjunction with other Xypex crystalline waterproofing products. Gamma Cure may be used as an alternative to water curing for certain Xypex applications. It is also used to accelerate the Xypex crystallization process. Xypex Gamma Cure acts as an evaporation retardant by retaining the maximum amount of moisture in the Xypex coating. It also provides a catalyst for the reaction with the Xypex crystalline waterproofing treatment. It is a self-dissipating (2 – 3 days) non-film forming product.

Advantages of Xypex

- Accelerate Xypex crystallization process

- May be used as an alternative to water curing for certain applications

- Retains the maximum amount of moisture in the Xypex coating

- Self-dissipating (2-3 days), non-film forming

Recommended for

- Applications where water-curing is not possible

- Hot, dry, windy conditions

- Vertical surfaces

Packaging

Available in 1 U.S. gallon (3.79 litre) bottles and 5 U.S. gallon (18.95 litre) pails.

Coverage

One U.S. gallon (3.79 litres) of Gamma Cure when diluted with water will cover approximately 800 sq. ft. (75 m2).

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is one year when stored under proper conditions.

Gamma Cure Application Details

Please refer to the Application Procedure section of the Product Data.

General Resources

Kunda chimney

Chimney that was constructed in 1959 out of reinforced concrete and stands 80 meters high, upper part had damages and needed repairs. Damaged concrete was removed, rebar corrosion was eliminated and missing concrete was restored using the repair mortar. Xypex Concentrate and Xypex Gamma Cure was used under the surface finish for protection and waterproofing.

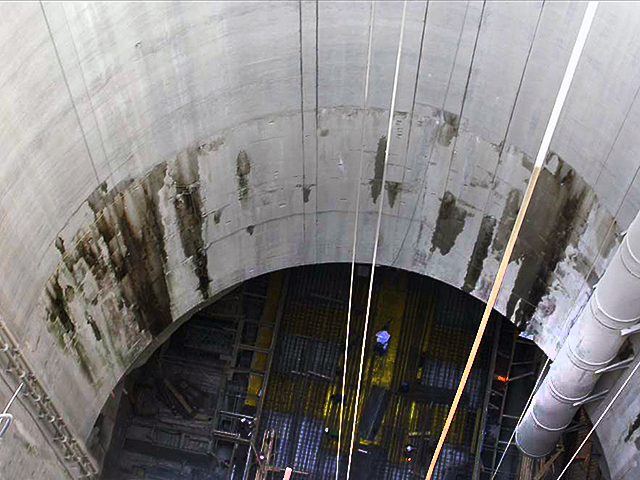

Cern Point 5 Nuclear Research Centre

The Cern Project was a test carried out by scientists to try and re-create “The Big Bang”. As another product was unable to penetrate into the porous concrete, Xypex was requested. Xypex Patch'n Plug was applied to several cracks in the construction of underground chambers, and Xypex Concentrate, Modified, and Gamma Cure were used to treat the concrete surface.

Lower Meramec Wastewater Treatment Plant

Once all joints and cracks had been repaired, the entire interior concrete surface of the lift station—up to 117 feet—was treated with a three-product system consisting of a base layer of Xypex Concentrate, a reinforcing layer of Xypex Modified and a final treatment of Xypex Gamma Cure, a curing accelerant and evaporation retarder. Approximately 34,000 ft2 of concrete were treated with Xypex products, amounting to about 21,000 pounds of product.

Stumers Creek Culverts

As part of flood repairs to David Low Way just outside of Coolum, new culverts were constructed as part of the road upgrade for improved flood prevention and tidal overflow. Test results on the 50 MPa concrete of the western-facing wing walls, Apron & Slab failed to meet with compressive strength tolerances of Transport and Main Roads specification. Due to the aggressive nature of the marine environment, Xypex Concentrate, Xypex Modified and Xypex Gamma Cure were selected to rehabilitate with western-facing wing walls, aprons and slab, to increase durability and improve the compressive strength.

Funkers Crossing

As part of flood repairs to New England Highway just outside of Stanthorpe, new culverts were constructed as part of the road upgrade for improved flood prevention. Test results on the 50 MPa concrete failed to meet with compressive strength tolerances of Transport and Main Roads specification. Xypex Concentrate, Xypex Modified and Xypex Gamma Cure were selected to rehabilitate the concrete to increase durability and improve the compressive strength. Raw Worx Pty Ltd were contracted to carry out the surface preparation and application of material to approximately 600 m² of concrete surface.

Projects Using This Product

Lower Meramec Wastewater Treatment Plant

The entire interior concrete surface of the lift station—up to 117 feet—was treated with a three-product system consisting of a base layer of Xypex Concentrate, a reinforcing layer of Xypex Modified and a final treatment of Xypex Gamma Cure, a curing accelerant and evaporation retarder. Gamma Cure is often used to help provide optimal curing conditions for Xypex coating products where water curing is difficult, particularly on vertical surfaces.

Parnell Baths

Xypex Patch’n Plug was used to stem water flow through the old seawall of the balance tank under the wooden decking, while the common pool wall within the balance tank was coated with two coats of Xypex Concentrate/Gamma Cure to address fine cracks and extend the serviceable life of this popular seawater pool.

Sacramento Kings – Golden 1 Center

A technical sales representative for Xypex confirmed that an application of Xypex Concentrate applied at 2.0 lb/sq.yd. followed by a heavy spray of Xypex Gamma Cure within four hours would serve as the stand-alone waterproofing mechanism for the pile caps at this critical juncture for water intrusion.

Stumers Creek Culverts

New culverts were constructed as part of the road upgrade for improved flood prevention and tidal overflow. Due to the aggressive nature of the marine environment, Xypex Concentrate, Xypex Modified and Xypex Gamma Cure were selected to rehabilitate with western-facing wing walls, aprons and slab, to increase durability and improve the compressive strength.

Cobertura Fluida of Rio Art Museum (M.A.R.)

The concrete pouring of this slab was performed in a single day within a uninterrupted 13-hours of concrete placement to prevent cold joints. This 320 cubic meters of concrete was made with 2,350 kg of Xypex Admix C-500, silica fume and polypropilene fibers. Part of the water of the concrete was replaced with ice, and cured with 200 kg of Xypex Gamma Cure in order to minimize cracking.

Umi Bridge

This bridge structure on the Markham Valley Highway showed signs of leeching and water permeation on the soffit of the deck, resulting in fine cracking of the concrete. Xypex Concentrate and Xypex Gamma Cure were selected not only because of their superior waterproofing capabilities but because they could be applied under adverse weather conditions and bridge service would not be interrupted.