Microbial induced corrosion can seriously reduce the service life of concrete sewer structures and wastewater treatment plants.

- Long retention sewer lines

- Manholes

- Headworks

- Lift stations

- Drop structures

- Enclosed sewage plant structures

For protection of concrete in severe sewage conditions.

Xypex Bio-San is a unique way of protecting concrete in harsh sewage conditions where hydrogen sulphide causes microbial induced corrosion (MIC). No other admixture combines potent antimicrobial properties with Xypex crystalline waterproofing technology to offer protection of concrete sewer and wastewater structures.

Xypex Bio-San contains mineral solids that remain permanently fixed within the concrete throughout the life of the sewage structure. These kill acid-generating microbes such as Thiobacillus that proliferate in H2S conditions thus preventing microbial induced corrosion. Combined with Xypex’s proven crystalline technology, Bio-San will protect concrete from infiltration and exfiltration as well as resisting acid and sulphate attack. After placement and curing, the crack-healing properties of Xypex will continue to function throughout the service life of the concrete.

As with all Xypex Admix products, Bio-San is added at the time of concrete batching, avoiding the potential quality issues of liners or coatings and eliminating schedule delays for surface preparation. As a one-component product, Bio-San simplifies the production process for pre-cast structures.

Xypex Bio-San is recommended for use in sewage systems especially in areas where H2S gas is likely to accumulate. This includes sewer lines with long retention times (flat, long, low flow) and sealed or unvented manholes. It will also include areas of high turbulence such as lift stations, drop structures, force main outflows and head works as well as various areas within wastewater treatment plants.

Xypex Megamix II with Bio-San is a resurfacing mortar specifically designed for the restoration of deteriorated concrete surfaces caused by microbial induced corrosion, abrasion/erosion and chemical attack. It is formulated for ease of application, superior bond, low shrinkage, high strength and resistance to microbial, acid and sulphate attack. Xypex Megamix II with Bio-San is a one component mortar and can be spray or trowel applied at a thickness of 10 – 50 mm per layer. The high performance characteristics of Megamix II with Bio-San are enhanced by Xypex’s unique crystalline waterproofing and protection technology. In most applications, such as manhole resurfacing, Megamix II with Bio-San can be used to replace epoxy linings and calcium aluminate repair mortars. Learn More about Megamix II with Bio-San

Downloads

For Bio-San product inquiries, please contact a Xypex distributor in your region.

Proven Technology

Kills the acid-generating microbes present in sewage environments

Independent testing showed that in concrete treated with Xypex Bio-San the presence of the sewer bacteria Thiobacillus Novellus (Starkeya Novella) was substantially reduced.

Protects concrete in areas of H2S buildup

Specimens of concrete treated with Xypex Bio-San as well as untreated concrete were hung in the enclosed sedimentation tanks at a wastewater facility with H2S concentrations of 20 to 70 ppm. The photos of the untreated concrete show the extent of the microbial induced corrosion after 6.5 years. After 10 years, the concrete treated with Xypex Bio-San had 9 times less corrosion than the untreated concrete, and continued to function at full efficacy.

Contains Crystalline Technology

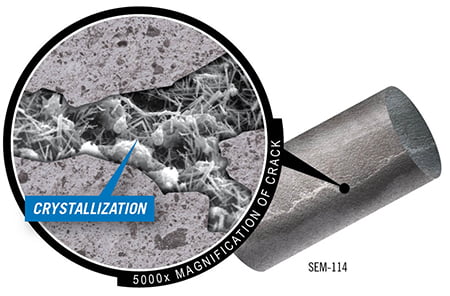

Xypex Bio-San contains the same unique crystalline technology as all Xypex Admix products. Xypex treated concrete resists extreme hydrostatic pressure, protects concrete against aggressive chemicals such as acids or sulphates and self-heals static cracks up to 0.5 mm.

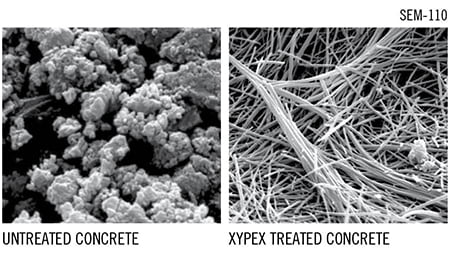

In a site test, Xypex treated and untreated samples were analyzed using Scanning Electron Microscopy. Xypex treated samples showed conclusive evidence of the dense crystalline matrix typical of Xypex Crystalline Technology.

Self-heals cracks up to 0.5 mm

Concrete panels were cast and then cracked by force after which they were subjected to the ponding of water to measure the flow through the crack. After four days the 0.38 mm crack on the Xypex treated sample had stopped leaking completely. The 0.25 mm crack in the control sample continued to leak after 25 days.

Protects concrete in acidic conditions

Cement mortar samples containing Xypex were subjected to 5% sulphuric acid for up to 12 weeks. Compared to untreated control samples, the weight loss caused by acid attack was reduced by 48%. In a further test on a 30% fly-ash mortar, the weight loss was reduced to 53%.

Protects concrete in sulphate environments

Samples of both Xypex treated and untreated concrete were placed in a highly concentrated sulphate solution. After 4 months the untreated samples experienced a weight loss of 4,800 g/m2 whereas the Xypex treated samples only lost between 5 g/m2 and 50 g/m2, showing no visible signs of surface deterioration.

Prevents infiltration & exfiltration of liquids even under extreme hydrostatic pressure

When subjected to 107 m (350 ft) of hydrostatic pressure Xypex treated samples completely resisted the flow of water and only allowed water penetration of 1.5 mm (0.06 in). Conversely, untreated control samples started leaking within 24 hours.

Bio-San Projects

American Furniture Manholes

American Furniture Manholes

Xypex Bio-San was chosen because it provides the precast sewage elements with protection against microbial induced corrosion and aggressive chemicals, as well as waterproofing and crack healing properties. The precast manufacturer reported that there were no operational or fabrication issues associated with including Xypex Bio-San in the wet cast mix.

Chatham Park WWTP

Chatham Park WWTP

Due to the potentially high levels of H2S in the Bioreactor McKim & Creed, a high build acid resistant coating was specified to protect the concrete. Bowen Engineering proposed to the engineers that Xypex Bio-San as an alternate because it contains Xypex’s antimicrobial crystalline technology. This technology also protects the concrete from microbial induced corrosion by killing the acid-producing bacteria. Thus, Xypex Bio-San provides similar protection of the concrete while eliminating the long term maintenance requirements associated with periodic replacement of protective coatings.

Fairchance Sewer Line Extension

Fairchance Sewer Line Extension

For this sewer line extension, the manholes along the force main required protection from microbial induced corrosion. Liners or coatings would normally be used to perform this function. As these are expensive and time consuming to install, the engineers decided to specify the inclusion of Xypex Bio-San admixture in the pre-cast concrete. Apart from the performance features of Bio-San it is also added at the time of concrete batching which means there is no need for the installation and welding of liners; this brings significant savings in time and expense.

River Islands Sewage Pump Station

River Islands Sewage Pump Station

Xypex Bio-San was proposed by PACE Advanced Engineering and then chosen by the City of Lathrop as an alternative to the specified system. Bio-San contains Xypex’s antimicrobial crystalline technology. This technology kills the Thiobacillus bacteria which cause the acid corrosion of concrete as well as preventing the infiltration of ground water and exfiltration of sewage liquid. As Bio-San is added to the concrete at the time of batching significant cost and construction schedule savings were achieved when compared to the initially specified epoxy coating: there was no need to install and detail the interior coating.

Roaring Fork Club – Lift Station

Roaring Fork Club – Lift Station

The Roaring Forks club lift station at Basalt Colorado was designed to include Xypex Bio-San in the concrete mix. This provides both protection against microbial induced corrosion and watertight, chemically protected concrete. Bio-San is added at the time of the concrete batching thereby saving considerable time and cost compared to traditional surface coatings and liners. As an admixture, it has no adverse effect on the plastic or hardened properties of concrete.

South Lathrop Commons Center Sewage Pump Station

South Lathrop Commons Center Sewage Pump Station

In order to protect the concrete structure from microbial induced corrosion and to achieve water tightness Xypex Bio-San was added to the concrete mix at the Jensen Precast’s plant at the time of batching. The Bio-San contains antimicrobial crystalline technology which both kills the acid-producing microbes which proliferate in sewage structures as well as providing watertight, chemically resistant concrete with crack-healing properties.