Back to Search Results

Marine Structures

Singapore Marina Barrage

More than 7,000 kg of Xypex Megamix II were used to shape and protect the new fins of the Barrage gates. Specially formulated to produce a high strength, low shrink mortar with high chemical resistance and superior bond characteristics, Xypex Megamix II was the only product available in the market that could applied to the very fine (1 mm) tolerances specified for the barrage, whilst its superior ability to withstand the harsh chemical and mechanical marine environment conditions contribute incrementally to the durability of the fins of the barrage.

Project Sheet

Project Sheet

PDF

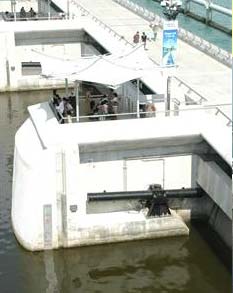

After 20 years of meticulous planning, design and construction, the $220+ million Marina Barrage has recently become operational, creating Singapore's 15th reservoir out of the iconic Marina Bay.

Now having the largest catchment of all of Singapore's reservoirs, the influx of rain water will eventually flush out most of the Marina Bays saline waters, with the residual being held at the bottom by the less dense fresh water.

Comprised of nine steel crest gates, each 30 m wide, the barrage spans the 350 m wide Marina Channel, separating seawater from freshwater and acting as a tidal barrier to keep out peak tides. Also forming part of the facility and in the event of a coincidence of heavy rains and high tides, seven gigantic vertical-shaft, axial flow pumps, with a combined capacity of 280 m3 per second will pump excess storm water into the sea.

More than 7,000 kg of Xypex Megamix II were used to shape and protect the new fins of the Barrage gates. Specially formulated to produce a high strength, low shrink mortar with high chemical resistance and superior bond characteristics, Xypex Megamix II was the only product available in the market that could applied to the very fine (1 mm) tolerances specified for the barrage, whilst its superior ability to withstand the harsh chemical and mechanical marine environment conditions contribute incrementally to the durability of the fins of the barrage.

Now having the largest catchment of all of Singapore's reservoirs, the influx of rain water will eventually flush out most of the Marina Bays saline waters, with the residual being held at the bottom by the less dense fresh water.

Comprised of nine steel crest gates, each 30 m wide, the barrage spans the 350 m wide Marina Channel, separating seawater from freshwater and acting as a tidal barrier to keep out peak tides. Also forming part of the facility and in the event of a coincidence of heavy rains and high tides, seven gigantic vertical-shaft, axial flow pumps, with a combined capacity of 280 m3 per second will pump excess storm water into the sea.

More than 7,000 kg of Xypex Megamix II were used to shape and protect the new fins of the Barrage gates. Specially formulated to produce a high strength, low shrink mortar with high chemical resistance and superior bond characteristics, Xypex Megamix II was the only product available in the market that could applied to the very fine (1 mm) tolerances specified for the barrage, whilst its superior ability to withstand the harsh chemical and mechanical marine environment conditions contribute incrementally to the durability of the fins of the barrage.