Why Xypex for Wastewater Collection & Treatment Structures

Meeting the Challenge

Protecting Critical Wastewater Infrastructure

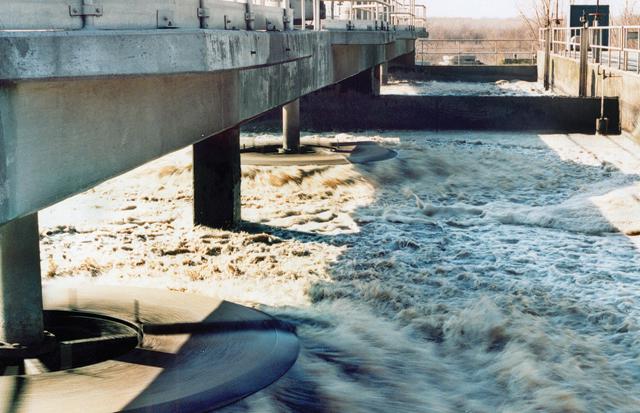

Microbial induced corrosion and water infiltration are the two major problems common to sewage collection and wastewater treatment structures. Unattended or poorly treated, these problems result in the rapid deterioration of concrete structures with the consequence of costly rehabilitation and significantly reduced service life. It’s a situation and challenge well known to engineers and municipalities the world over as they address the ever-increasing demand for structures that will meet the growing demands of industry, the environment, economics, and the need for improved water supply and sanitation.

Xypex has over 50 years experience in the waterproofing and protection of the concrete infrastructure of cities and is up to the challenge. Our Xypex Crystalline Technology has been proven in rehabilitated as well as new sewage and wastewater treatment structures and is considered the best at handling chemical attack in severe biochemical conditions and resisting water infiltration even under extreme hydrostatic pressure.

Xypex products play a major role in the prevention and treatment of problems common to both segments in Wastewater Infrastructure: the Sanitary Sewer Collection System and the Wastewater Treatment Plant. Microbial induced corrosion and water infiltration are major problems to both segments that Xypex can improve.

Microbial Induced Corrosion

Slow flow and long retention times in a sanitary sewer are the precursor to microbial induced corrosion in sewer and wastewater treatment structures.

During transit time, dissolved hydrogen sulfide (H2S) is produced in the waste flow liquid by sulfate-reducing bacteria under anaerobic conditions. Hydrogen sulfide gas is released into the sewer atmosphere by turbulence and dissolves in the moisture and slime on the sewer crown. Bacteria turn the sulfur compounds into sulfuric acid which attacks the concrete by means of acidic corrosion and longer term through expansive sulfate attack. This causes the concrete to slowly corrode and self-destruct.

Sewage Collection Structures

- Manholes

- Sewer Pipes

- Pump/Lift Stations

- Combined Sewer Overflow & Interceptors

Wastewater Treatment Structures

- Headworks

- Grit Chamber

- Primary, Secondary & Tertiary Treatment

- Disinfection Structures

- Digesters

Infiltration & Exfiltration

A common source of water infiltration into manholes and sewer line is cracks or displaced joint lines caused by frost heaving, ground traffic or settlement. Water infiltration can increase total flow by as much as 25% – 30% which significantly raises chemical treatment costs while at the same time potentially creating capacity problems for wastewater plants.

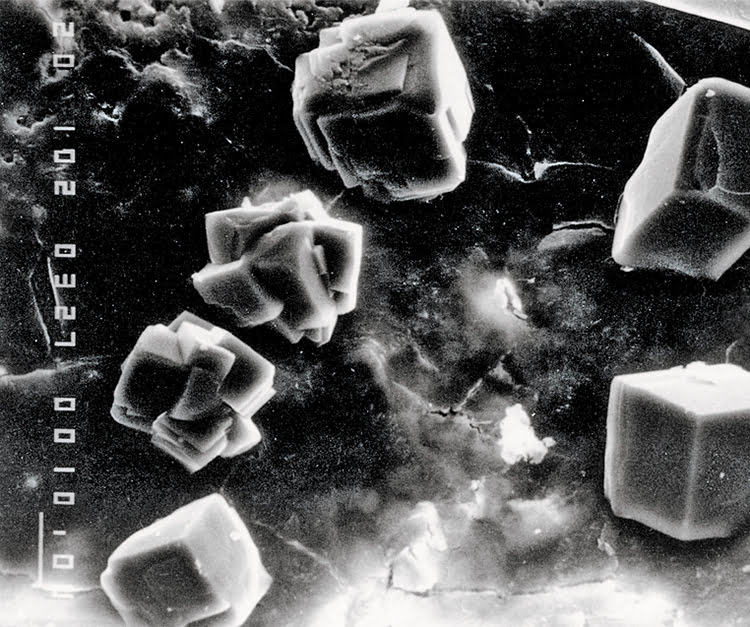

Xypex Crystalline Technology

Xypex products use the natural porosity of concrete and chemical diffusion to penetrate its pores and capillaries. Inside the concrete, Xypex chemicals react with the by-products of cement hydration to form a non-soluble crystalline structure deep within the substrate. In this condition, the concrete becomes impermeable, preventing the penetration of liquids and chemicals from any direction even under extreme hydrostatic pressure. The chemical resistant properties of the crystalline structure help to reduce the effects of microbial induced corrosion.

The Xypex Advantage

Xypex Crystalline Technology works inside the concrete, thereby avoiding the problems typical of traditional barrier products.

- Resists microbial induced corrosion and chemical attack

- Not subjected to the deterioration problems encountered by membranes

- Not dependent of surface adhesion to achieve its waterproofing effect

- Xypex is permanent and reactivates whenever water is present

- Can be applied on negative or positive side of concrete surface

- Self-heals static cracks up to 0.5 mm (0.02 in)

Proven Performance Worldwide

Comprehensive quality systems and standards along with thorough testing in the lab and the field have resulted in Xypex’s highly respected position in the concrete industry. Xypex has been extensively tested by independent testing laboratories in the U.S., Canada, Australia, Japan, Europe and other countries.

![]()

Xypex Admix for New Concrete Construction

Xypex Admix is the preferred choice for installing Xypex Crystalline Technology into new concrete structures for the collection and treatment of wastewater. Because Xypex Admix is blended into the mix at the time of batching, it becomes an integral part of the entire concrete matrix reducing the potentially damaging effects of water infiltration and microbial induced corrosion. Flexibility in application means Xypex Admix can be installed in precast products such as pipes, manholes, and lift stations or cast-in-place structures in wastewater treatment plants.

Bio-San for Concrete Waste Water Structures

An antimicrobial crystalline admixture for the maximum protection in severe sewage conditions. Xypex Bio-San is a unique combination of potent antimicrobial properties with Xypex Crystalline Technology for use in areas where H2S gas is likely to accumulate.

Xypex Admix Advantages

- Permanent integral waterproofing

- Resists chemical attack

- Enhances concrete durability

- Value engineering

Discover the full potential

of Additive products.

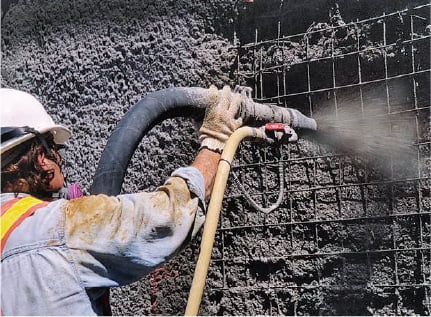

Rehabilitation & Repair

Xypex’s coating systems and repair products enable municipalities, engineers and contractors to economically and confidently rehabilitate inefficient or deteriorating wastewater collection and treatment structures. Xypex Concentrate and Modified are applied as slurry coatings to the surface of the concrete. Unlike other materials that need a dry substrate, Xypex waterproofing concrete products require a moist surface – conditions typical of existing wastewater structures. Xypex Patch’n Plug, Concentrate Dry-Pac and Megamix products are specifically designed to permanently repair concrete defects such as honeycombs, static cracks and faulty cold or construction joints; they also fill tie-holes and seal around pipe penetrations. Megamix II with Bio-San contains bioactive mineral solids that provide antimicrobial protection for extreme sewage environments.

Xypex Coating Advantages

- Doesn’t require a dry surface

- Apply to either side of the concrete

- Won’t puncture, blister or tear

- No costly surface priming or leveling

- Sealing, lapping or finishing is not required

- No need for protection during backfilling

- Permanent waterproofing

- Enhanced concrete durability

- Doesn’t contain VOCs

Other Accessory Products are also available.

SEE XYPEX PRODUCTS

Find the right product

for your project.

Alegria Wastewater Treatment Plant

City of Nelson Sewage Plant Addition

Nitra Sewage Treatment Plant

J.A.M.E.S. Wastewater Treatment Facility

Secondary Containment Tanks

Goldbar Wastewater Treatment Plant

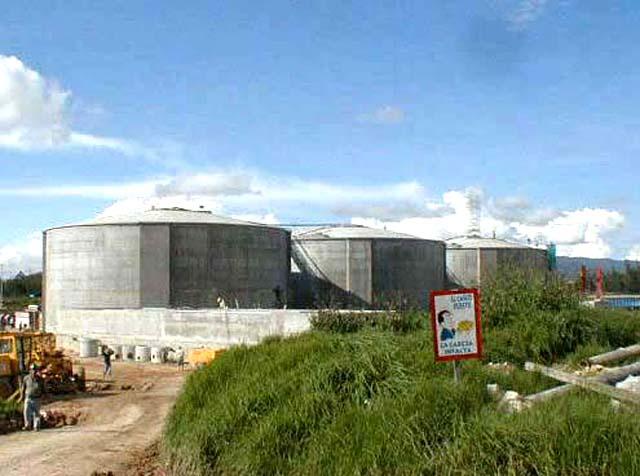

Bogotá Wastewater Treatment Plant

Mio Wastewater Treatment Plant

Showa Glove Factory