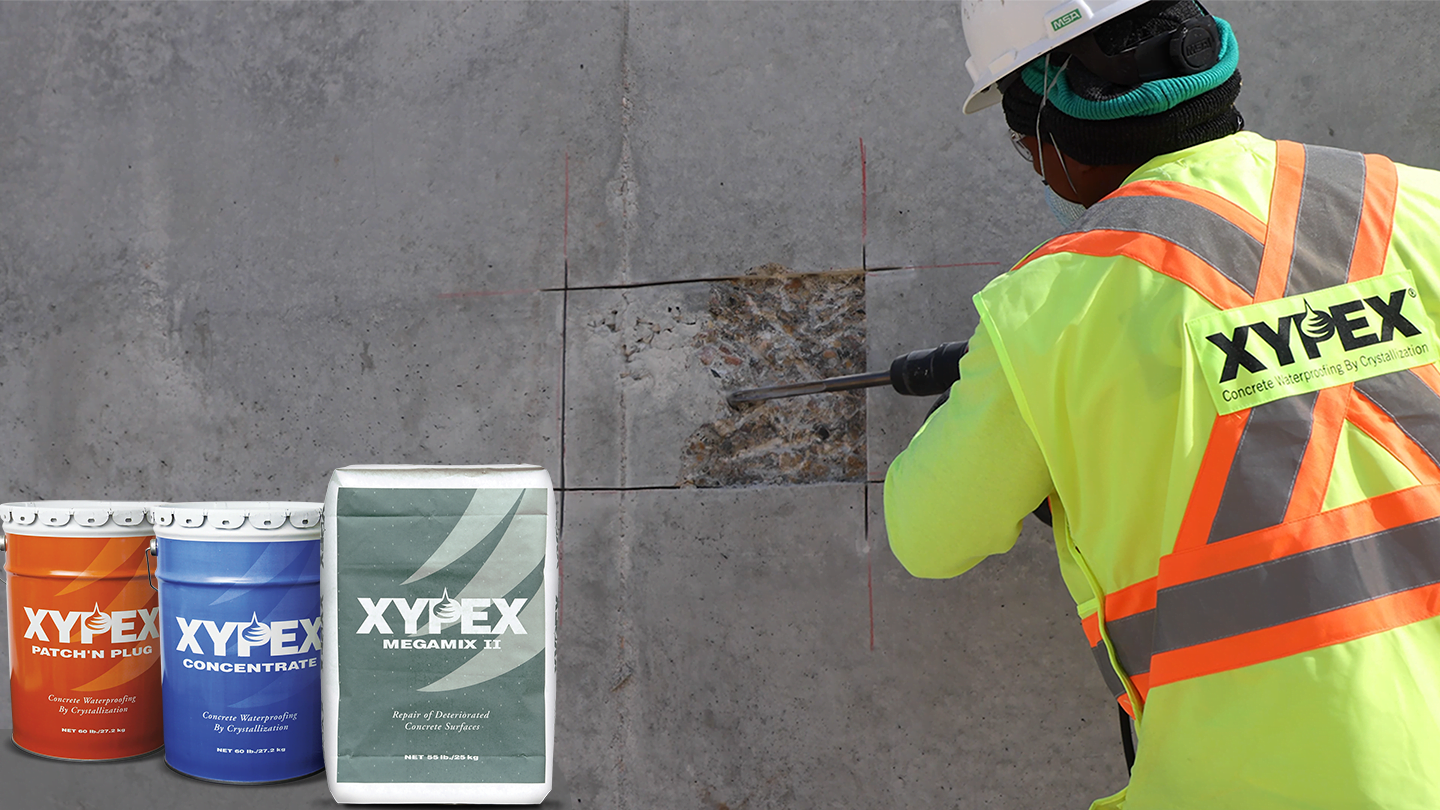

Patch’n Plug

Xypex Patch’n Plug is a specially designed, fast-setting hydraulic cement compound for concrete patching and repair. It stops flowing water in seconds and is used to seal cracks, tie holes, and other defects in concrete. The high performance characteristics of Patch’n Plug are enhanced by Xypex’s unique Crystalline Waterproofing Technology.

Advantages of Xypex

- Single component (simply add water)

- Very rapid setting

- Contains Xypex’s unique crystalline chemistry

for self-healing of cracks and other defects - Quick return to service of water holding structures

- Cement based – compatible with concrete and

masonry substrates - Non-toxic

- No VOCs

- NSF 61 certified

Recommended for

- Stopping an active flow of water through cracks

- Repair of concrete substrates before the application of Xypex coating materials

- Repair of leaking construction joints

- Sealing around pipe penetrations

Packaging

Available in 20 lb. (9.1 kg) pails and 50 lb. (22.7 kg) pails.

Coverage

One 50 lb. (22.7 kg) pail of Xypex Patch’n Plug will produce 0.45 cubic feet (0.0127 cu. metres) of mortar.

Storage

Xypex products must be stored dry at a minimum temperature of 45ºF (7ºC). Shelf life is two years when stored under proper conditions.

Patch'n Plug Application Details

Please refer to the Plugging & Patching Instructions section of the Product Data

Xypex recommended procedures for repairing slabs, walls and other flat concrete surfaces that have dry or leaking cracks and cold/construction joints.

Xypex recommended procedures for repairing wall to slab interface joints and other 90 degree concrete joints; including dry or leaking joints.

Xypex recommended blends of Concentrate and Patch’n Plug to create a longer pot life workable repair mortar that can replace Xypex Concentrate Dry-Pac for many Xypex repair scenarios and procedures.

Xypex recommended procedures and general directions for repairing standard, small to large sized spalls, honeycombs, and other deficiencies.

Xypex recommended procedures for repairing water leaks between conduit, pipe and other utility features (including steel, iron, PVC and HDPE piping) and the concrete elements they pass through.

Xypex recommended procedures for repairing leaking form-ties based on the typical “Plastic Cone Snap Tie” forming tie system (can be modified for other styles of form-ties).

Xypex recommended Estimating Table is a guide only. Actual usage may vary according to the project.

General Resources

Sea La Vie Hotel

This project is located in Ksamil, Saranda, and consists of the construction of a 4 story hotel building with 2 underground floors, with a basement area of 1200 m2. The location very close to the coastline brought special engineering challenges, due to the difficult terrain conditions and high groundwater levels.

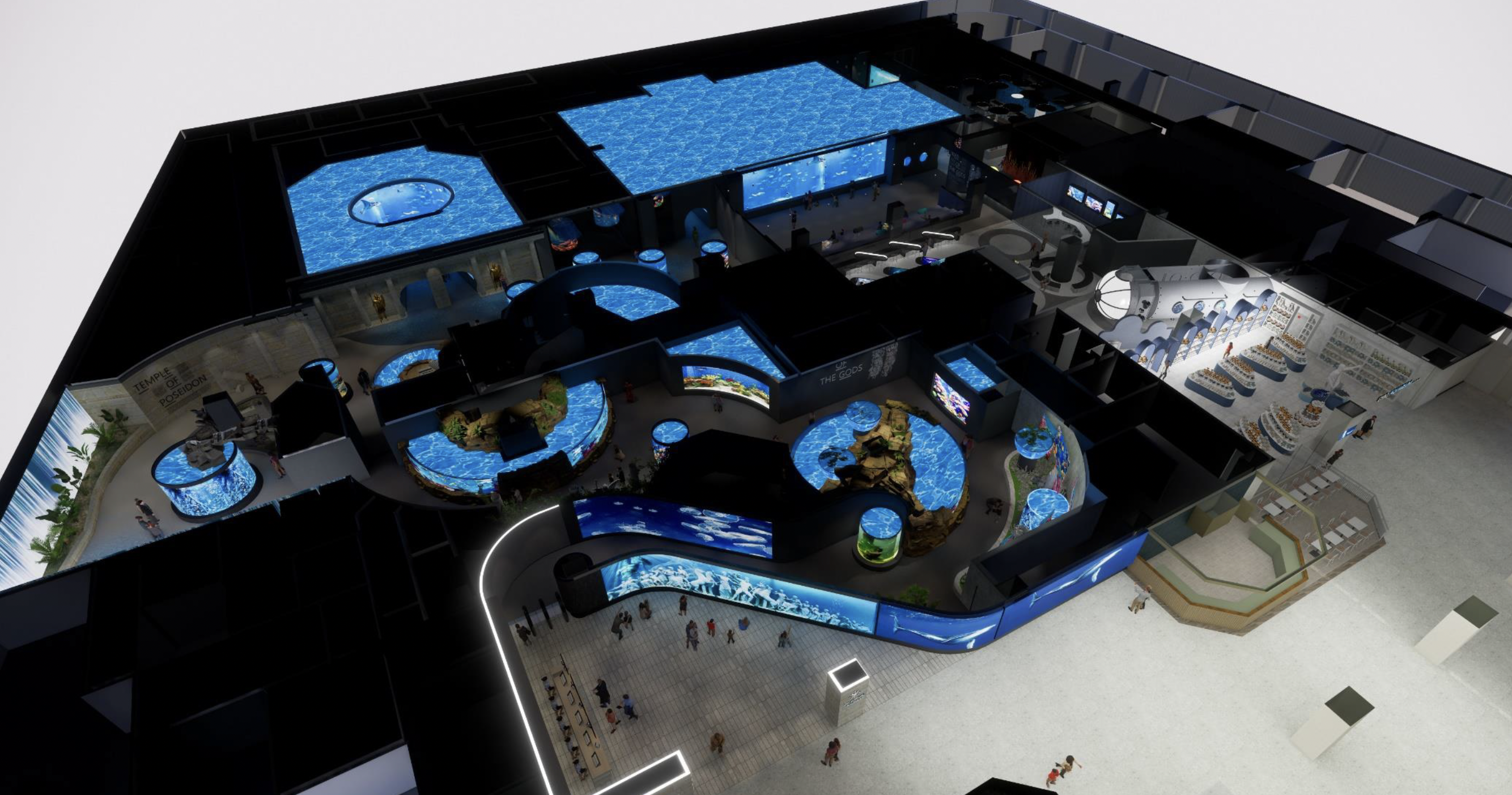

Daejeon Expo Aquarium

The Daejeon Expo Aquarium, located on the first basement floor of the Daejeon Science Complex in Daejeon City, Korea, spans 6,623 square meters and has quickly become a prominent attraction. This new construction features a unique two-floor design, including a 94-meter-long submerged tunnel offering panoramic views of marine life.

Manure Holding Tanks

This project involved the application of Xypex crystalline waterproofing across 60,000 sq ft of concrete manure holding tanks in Clovis, New Mexico, for Vanguard Ag, a developer specializing in agricultural waste-to-energy systems. The tanks support anaerobic digestion, a process that breaks down farm and food waste to produce renewable biogas and agricultural byproducts.

Réservoir d'eau potable Saint-Jean - Trois-Rivières

The City of Trois-Rivières awarded Construction Deric a major contract to renovate part of its drinking water network facilities in the west sector, totalling just over $77 million. The 70-year-old reservoir showed signs of hairline cracks and joint seepage. A crucial part of renovating the Saint-Jean reservoir was addressing the concrete degradation and the cracks that had developed over decades of use.

Renovation of the Belvédère Swimming Pool

The Belvédère Municipal Swimming Pool in Tunis, Tunisia, underwent a significant renovation in 2024, blending modern infrastructure improvements with the preservation of a historic landmark. Owned by the Tunis Municipality and supervised by the General Directorate of Military Engineering, the project brought together an expert engineering team comprising consulting engineers Mr. Fredj and Mr. Adel Maatouk, Bicotec Ingénierie under the leadership of Rachid Nouri, and BIAT & Veritas Tunisia.

Projects Using This Product

The Rihand Dam

Being one of the oldest dams in India, the concrete of the dam body has experienced deterioration due to ageing and AAR (Alkali Aggregate Reaction) resulting in cracking and surface loss. Xypex’s unique crystalline technology was chosen as the preferred repair solution due to its cementitious nature and compatibility with concrete along with other technical reasons.

Sydney Harbour Tunnel

Commencing in September of 1991, repair systems using Xypex Concentrate and Patch’n Plug were used as part of an ongoing program of repair and maintenance of the North and South land driven tunnels and transition tunnels of this renown structure.

AASS Wastewater Treatment Plant

The walls of this plant were cast using the Machihembrado method. Because of this approach, Xypex Dry-Pac and Xypex Patch’n Plug were required to seal the construction joints. The same Xypex treatment was used on 518 m of cold joints and cracks. After these structural defects were repaired, the surfaces were treated with a two-coat application of Xypex Concentrate.

Canóvanas Filtration Plant

The thickening tank (92 ft. diameter by 15 ft. deep) of this filtration plant used Xypex Patch’n Plug to repair structural defects followed by a coating of Xypex Concentrate. Upon review, the Xypex treatment proved to be very successful, rendering the tank impenetrable by water.

Chehe River Mine

Xypex products were chosen to rehabilitate these pipes as they resist hydrostatic pressure, chemical attack and are a permanent solution thus avoiding future maintenance intervals and shutdowns. Additionally, they are used on wet concrete so removing the need to dry out the concrete before application. Xypex Patch’n Plug was used to seal active leaks in the pipe joints.

Fiat India Automobiles Private Ltd.

More than 13,000 lbs of Xypex Concentrate and 1,000 lbs of Xypex Patch’n Plug were used to waterproof a surface area of 60,000 sq.ft. Xypex was chosen for its additional benefit of chemical resistance and concrete durability enhancement.

Wastewater Tunnel Repair

The first phase of the project required the Bawax applicator to fill in all of the joints between the precast culvert sections with Xypex Patch’n Plug fast-setting hydraulic cement compound. Patch’n Plug stops flowing water in seconds and is used to seal cracks and other holes or defects.