Back to Search Results

Precast Structures

Taylor Shellfish Processing Facility

Shelton, Washington,

USA

Xypex Admix C-500 is providing built-in permanent protection against the harsh saltwater environment in the new wet processing facilities at Taylor Shellfish Farms. Saves construction time and eliminates future maintenance.

Project Sheet

Project Sheet

PDF

As a leader in sustainably farmed oysters, clams, mussels and geoduck, Taylor Shellfish Farms, based in Shelton, Washington, USA, continually strives to provide the highest quality, best tasting ‘Tide to Table’ experience possible. To meet the rising demand from wholesale and retail customers around the world, the firm continually reinvests in new processing facilities, aquaculture techniques, and tideland preservation.

Founded in the 1890s, Taylor Shellfish is in its fifth generation of Taylor family management and is the largest shellfish producer of farmed (aquaculture) shellfish in North America (fig 1). The firm employs more than 800 and owns and farms more than 15,000 acres of tidelands (fig 2) in Washington’s Puget Sound and up the coast to British Columbia, Canada. It also provides 90% of the North American shellfish industry’s ‘seed’ stock from its hatcheries in California and Hawaii.

Each year, Taylor Shellfish produces more than 150,000 gallons of shucked oyster meat (fig 3), 60 million live oysters, 12 million frozen oysters, 1.5 million pounds of mussels, five million pounds of clams, and one million pounds geoduck (pronounced “gooey-duck”).

Taylor operates eight retail restaurants and clam bars (fig 4) in Washington state, China, and South America. The firm supplies about 200 other restaurants in Washington and Oregon, as well as hundreds of others throughout the world via overnight deliveries. Taylor is one of the largest volume shippers in the Northwest, shipping the bulk of its production to Asian markets where it fetches top dollar.

Investment in Quality

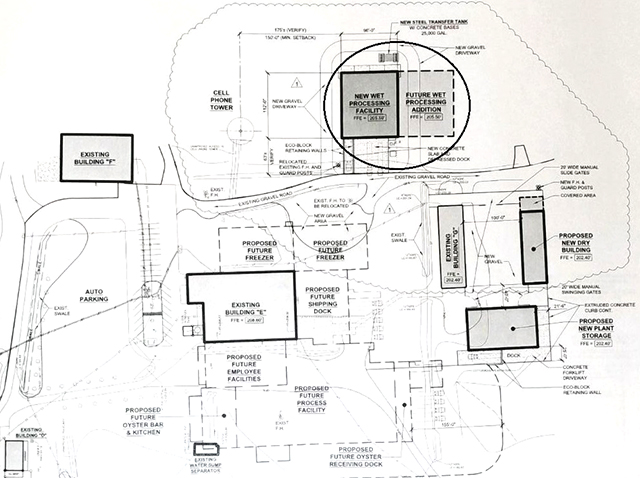

Among its latest improvements, Taylor Shellfish is adding storage space and an innovative new wet processing facility to its 200-acre headquarters site in Shelton (fig 5). The new multi-million dollar wet processing facility, in particular, will enable the firm to better meet demand with the freshest and safest possible products year-round.

“One of the biggest challenges we face is that our work is dependent on the tides (fig 6),” explains Austin Docter, Taylor’s director of processing. “Our oysters and other shellfish are underwater and inaccessible for long stretches. To counter this, we harvest as much as we can when the tides are out and store it on the beach or in other areas. This isn’t ideal because the shelf life is limited.”

The 28-year Taylor Shellfish veteran notes, “A better solution is to store the harvest in saltwater aquariums essentially so that the shellfish believes it’s still in the ocean. There is zero shelf life lost. And, we have found that if you provide the oyster with purified saltwater, it will actually purge itself of bacteria and other contaminants.”

According to Docter, about half of the shellfish harvest areas in Washington state are closed every summer due to high levels of bacteria, particularly vibrio parahaemolyticus. Vibrio occurs naturally in coastal waters and can accumulate in shellfish and, if consumed raw or undercooked, can cause a mild illness known as vibriosis.

These harvest area closures can lead to significant losses—amounting to millions of dollars in lost profit—for Taylor and other producers. “Our goal with this new wet processing facility is to allow our oysters to fully purge, enabling us to provide a bacteria-free oysters,” Docter continues. “That’s a pretty big deal. We have government officials visiting us to see what we’re doing here. It’s going to be major change for our industry by improving shellfish safety significantly.”

Taylor Shellfish worked with Food Facility Engineering and PSM Engineers to scale their prototype operation up to an 11,000-square-foot facility. Once completed in the spring of 2020, Taylor plans to immediately double the size of the facility by building an identical structure directly adjacent to the current project. The combined 22,000 square feet of innovative new wet processing will enable the firm to clean and ship more than 270,000 pounds of fresh shellfish per week.

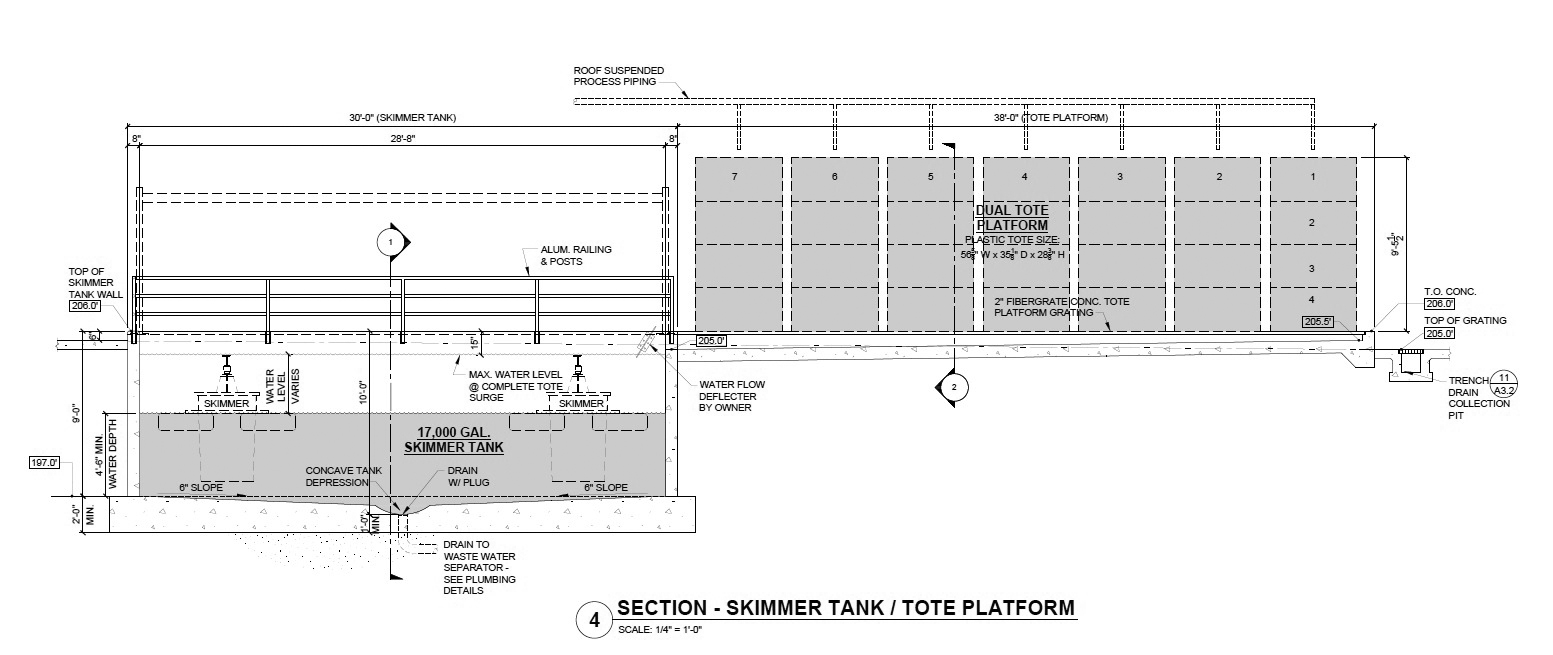

The key feature of the wet processing facility will be four large sloped platforms (each 380 ft2) where 224 plastic totes filled with newly harvested shellfish will be stored. The large totes will be continually filled with filtered and UV purified saltwater, allowing the shellfish to purge all waste products, including bacteria (fig 7).

Each tote platform will continually drain into its own 17,000 gallon skimmer tank that extends 10 feet (3 meters) bellow the floor level (fig 8). Biological waste will be skimmed from the surface and disposed of. The water will be recycled through filtration and UV sterilization and returned to the totes.

Built in Protection

When it came to choosing which material to use for the all-important skimmer tanks and tote holding platforms, Taylor turned to the general contractor—Mountain Construction, based in Tacoma, Washington—for advice.

“I relied on my general contractor’s advice to guide me,” Docter notes. “We discussed making the tanks, for instance, out of fiberglass, steel or concrete. Concrete offered many advantages, but I had concerns because I have lots of concrete around here that I have watched rot away to nothing over the years from salt exposure. So my main question was how are we going to solve that?”

According to Mountain Construction project manager Mike Swarthout, “The big question was what is going to stand up the longest based on how these tote platforms and tanks are going to be used. They will be continually exposed to saltwater, grit, and other contaminants—they need to be very durable.”

He continues, “The concern with concrete is it can degrade in saltwater environments and even the best concrete can develop cracks during curing or over time. We decided to use Xypex admixture for several reasons. First, by using an admix, we can be sure that the treatment is in 100% of the concrete we use. Second, Xypex enables any cracks that form to self heal and, finally, it also makes the concrete harder and more durable against salt and chemicals.”

Xypex Admix C-500, which was added to the ready-mix concrete in the mixer truck, consists of Portland cement and various active, proprietary chemicals that react with the moisture and the by-products of cement hydration to cause a catalytic reaction that results in the formation of non-soluble crystals that fill the natural pores and capillary tracts in concrete. This crystalline formation prevents the penetration of water and other liquids from any direction.

Mountain’s Mike Swarthout adds: “When we considered the alternatives, such as epoxy or poly coatings, Xypex is an integral part of the system so there is no future maintenance or reapplication like there would be with coatings. Logistically, it also saves time and labor because it’s mixed into the concrete we have to pour anyway (fig 9). We don’t have to schedule another crew to come in to coat it. Fewer steps means less chance for errors.”

According to Xypex northwest representative Stephen Keyser, Xypex is often used in applications where concrete will be exposed to potable water or food products. “Xypex products are nontoxic,” he notes. “They have been approved by NSF International, US Environmental Protection Agency, Agriculture Canada and many other government health agencies throughout the world for use on concrete structures that hold potable water or are in contact with foodstuffs.”

“What we’re doing here is a game changer,” Taylor’s Austin Docter emphasizes. “Our goal is to be able to continue to harvest shellfish throughout the summer months because we will be able to validate that we can remove potentially harmful bacteria. Others in the industry understand this process, but have not been able to scale it up to the extent we have. We are setting a new standard for product quality that’s going to set us apart even more.”

Through generations of experience, Taylor Shellfish has learned where and how to cultivate the best shellfish in the waters of the Pacific Northwest. Areas like Puget Sound, Hood Canal, Samish Bay and Willapa Bay have unique conditions that deliver shellfish with a distinctive taste and character that is coveted by chefs and consumers the world over.

Founded in the 1890s, Taylor Shellfish is in its fifth generation of Taylor family management and is the largest shellfish producer of farmed (aquaculture) shellfish in North America (fig 1). The firm employs more than 800 and owns and farms more than 15,000 acres of tidelands (fig 2) in Washington’s Puget Sound and up the coast to British Columbia, Canada. It also provides 90% of the North American shellfish industry’s ‘seed’ stock from its hatcheries in California and Hawaii.

Each year, Taylor Shellfish produces more than 150,000 gallons of shucked oyster meat (fig 3), 60 million live oysters, 12 million frozen oysters, 1.5 million pounds of mussels, five million pounds of clams, and one million pounds geoduck (pronounced “gooey-duck”).

Taylor operates eight retail restaurants and clam bars (fig 4) in Washington state, China, and South America. The firm supplies about 200 other restaurants in Washington and Oregon, as well as hundreds of others throughout the world via overnight deliveries. Taylor is one of the largest volume shippers in the Northwest, shipping the bulk of its production to Asian markets where it fetches top dollar.

Investment in Quality

Among its latest improvements, Taylor Shellfish is adding storage space and an innovative new wet processing facility to its 200-acre headquarters site in Shelton (fig 5). The new multi-million dollar wet processing facility, in particular, will enable the firm to better meet demand with the freshest and safest possible products year-round.

“One of the biggest challenges we face is that our work is dependent on the tides (fig 6),” explains Austin Docter, Taylor’s director of processing. “Our oysters and other shellfish are underwater and inaccessible for long stretches. To counter this, we harvest as much as we can when the tides are out and store it on the beach or in other areas. This isn’t ideal because the shelf life is limited.”

The 28-year Taylor Shellfish veteran notes, “A better solution is to store the harvest in saltwater aquariums essentially so that the shellfish believes it’s still in the ocean. There is zero shelf life lost. And, we have found that if you provide the oyster with purified saltwater, it will actually purge itself of bacteria and other contaminants.”

According to Docter, about half of the shellfish harvest areas in Washington state are closed every summer due to high levels of bacteria, particularly vibrio parahaemolyticus. Vibrio occurs naturally in coastal waters and can accumulate in shellfish and, if consumed raw or undercooked, can cause a mild illness known as vibriosis.

These harvest area closures can lead to significant losses—amounting to millions of dollars in lost profit—for Taylor and other producers. “Our goal with this new wet processing facility is to allow our oysters to fully purge, enabling us to provide a bacteria-free oysters,” Docter continues. “That’s a pretty big deal. We have government officials visiting us to see what we’re doing here. It’s going to be major change for our industry by improving shellfish safety significantly.”

Taylor Shellfish worked with Food Facility Engineering and PSM Engineers to scale their prototype operation up to an 11,000-square-foot facility. Once completed in the spring of 2020, Taylor plans to immediately double the size of the facility by building an identical structure directly adjacent to the current project. The combined 22,000 square feet of innovative new wet processing will enable the firm to clean and ship more than 270,000 pounds of fresh shellfish per week.

The key feature of the wet processing facility will be four large sloped platforms (each 380 ft2) where 224 plastic totes filled with newly harvested shellfish will be stored. The large totes will be continually filled with filtered and UV purified saltwater, allowing the shellfish to purge all waste products, including bacteria (fig 7).

Each tote platform will continually drain into its own 17,000 gallon skimmer tank that extends 10 feet (3 meters) bellow the floor level (fig 8). Biological waste will be skimmed from the surface and disposed of. The water will be recycled through filtration and UV sterilization and returned to the totes.

Built in Protection

When it came to choosing which material to use for the all-important skimmer tanks and tote holding platforms, Taylor turned to the general contractor—Mountain Construction, based in Tacoma, Washington—for advice.

“I relied on my general contractor’s advice to guide me,” Docter notes. “We discussed making the tanks, for instance, out of fiberglass, steel or concrete. Concrete offered many advantages, but I had concerns because I have lots of concrete around here that I have watched rot away to nothing over the years from salt exposure. So my main question was how are we going to solve that?”

According to Mountain Construction project manager Mike Swarthout, “The big question was what is going to stand up the longest based on how these tote platforms and tanks are going to be used. They will be continually exposed to saltwater, grit, and other contaminants—they need to be very durable.”

He continues, “The concern with concrete is it can degrade in saltwater environments and even the best concrete can develop cracks during curing or over time. We decided to use Xypex admixture for several reasons. First, by using an admix, we can be sure that the treatment is in 100% of the concrete we use. Second, Xypex enables any cracks that form to self heal and, finally, it also makes the concrete harder and more durable against salt and chemicals.”

Xypex Admix C-500, which was added to the ready-mix concrete in the mixer truck, consists of Portland cement and various active, proprietary chemicals that react with the moisture and the by-products of cement hydration to cause a catalytic reaction that results in the formation of non-soluble crystals that fill the natural pores and capillary tracts in concrete. This crystalline formation prevents the penetration of water and other liquids from any direction.

Mountain’s Mike Swarthout adds: “When we considered the alternatives, such as epoxy or poly coatings, Xypex is an integral part of the system so there is no future maintenance or reapplication like there would be with coatings. Logistically, it also saves time and labor because it’s mixed into the concrete we have to pour anyway (fig 9). We don’t have to schedule another crew to come in to coat it. Fewer steps means less chance for errors.”

According to Xypex northwest representative Stephen Keyser, Xypex is often used in applications where concrete will be exposed to potable water or food products. “Xypex products are nontoxic,” he notes. “They have been approved by NSF International, US Environmental Protection Agency, Agriculture Canada and many other government health agencies throughout the world for use on concrete structures that hold potable water or are in contact with foodstuffs.”

“What we’re doing here is a game changer,” Taylor’s Austin Docter emphasizes. “Our goal is to be able to continue to harvest shellfish throughout the summer months because we will be able to validate that we can remove potentially harmful bacteria. Others in the industry understand this process, but have not been able to scale it up to the extent we have. We are setting a new standard for product quality that’s going to set us apart even more.”

Through generations of experience, Taylor Shellfish has learned where and how to cultivate the best shellfish in the waters of the Pacific Northwest. Areas like Puget Sound, Hood Canal, Samish Bay and Willapa Bay have unique conditions that deliver shellfish with a distinctive taste and character that is coveted by chefs and consumers the world over.