Wastewater Tunnel Repair

Bawax has provided structural waterproofing for new construction and renovations for more than 30 years. The firm was one of the first licensed applicators of Xypex in Germany and later became a distributor. Xypex Admix C-1000 NF was the first and remains the only admixture sealant approved by Germany’s top certification organization, Deutsches Institut für Bautechnik (DIBt).

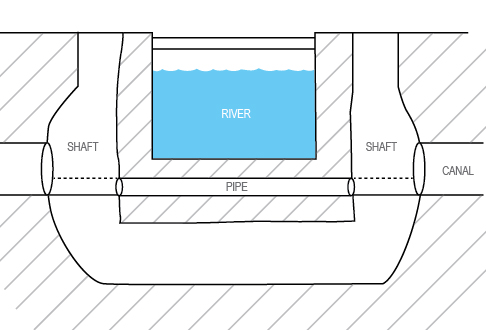

In 2014, the Hemer department of waste water, as part of a routine inspection by remote camera, discovered that a large amount of water was leaking into the precast box culvert, known as a Düker in German. Each of the culvert’s 16 precast segments were leaking profusely as a result of deteriorated seals and constant hydrostatic pressure imposed by the river flowing just above.

According to Hemer site manager Astrid Hanzen, who oversees the maintenance and repair of the city’s wastewater infrastructure, the wastewater culvert under the Oese River was leaking approximately 20 liters (5.3 gallons) per second, amounting to more than 1.7 million liters (449,000 gallons) per day.

At that rate, the leaking culvert was costing the city tens of thousands of Euros per year in extra wastewater processing fees. The city considered a number of solutions to fix the culvert, including complete replacement, a spiral wound lining, and various repair coatings.

Replacement ruled out

Replacement of the culvert, which had been installed in 1979, was ruled out for multiple reasons, including:

• Temporary rerouting of the river would be required;

• Traffic—more than 30,000 vehicles per day—would be disrupted for approximately four months; and a

• Cost of about €400,000 ($456,269 USD).

While relatively small at just 16 meters (52 feet) in length and 1 m x 2 m (3.3 ft x 6.6 ft) in cross section, the culvert’s position under the Oese River and below a complex urban intersection made it a challenging repair project. Fortunately for Hemer, the ultimate solution had already been used to repair several of the city’s leaking manholes.

“When Hemer came to us with this challenge, we had no doubt we could solve this problem using Xypex Crystalline Waterproofing products,” says Georg Schaefer, managing partner of Bawax GmbH, a structural waterproofing contractor based in Celle, Germany. “We had fixed some leaking manholes in Hemer using Xypex a few years ago. However, the location of the culvert four meters below ground and under the river posed a number of unique problems, including a continuous influx of water during the project, the tight working space, and need to manage heavy vehicle traffic around the work site.”

Although Hanzen and her staff was aware that Xypex waterproofing products had been used on other smaller projects in the city, they carried out their due diligence to verify that it could solve the aggressive leaks in the culvert.

“We researched how Xypex had been used on other similar projects by studying journals and making phone calls to other communities that have already used the system, asking for their opinions and experiences,” Hansen notes. “The results were consistently positive so we contracted with Bawax to make the repair.”

Tight repair window opens

It was determined that the six-week school break in the summer of 2017 would be the optimal time to carry out the repair. Traffic would be somewhat reduced and the chance of rain would be less. The crew would still have to deal with the continuous inflow of water from the river; however, at least storm runoff would be less likely to be an issue. Or would it?

“Of course, we were hit with unusually

heavy summer rain storms twice during

the project,” recalls Schaefer. The summer

storms each set the project back

several days. He notes that his firm deployed

a three-person crew to carry out

the repairs. Two traffic lanes had to be

redirected around two manholes, which

was managed by the city’s traffic control

officers.

“We opened manholes at either end of the

culvert and used the manhole at the upper

end of the culvert to provide work access

and the manhole at the lower end to pump out water and blow in fresh air,” Schaefer

explains. The culvert had to be cleaned of

dirt and debris and pressure washed to

provide a clean joints and surfaces.

Patch’n Plug stops the leaks

The first phase of the project required the

Bawax applicator to fill in all of the

joints between the precast culvert sections

with Xypex Patch’n Plug fast-setting

hydraulic cement compound.

Patch’n Plug stops flowing water in seconds

and is used to seal cracks and other

holes or defects.

At only one meter high, the culvert was a

tight space to work in. The applicator used

a low dolly to move inside the culvert,

which also kept him out of the ever-present

water that continued to rush in. Excess

water was pumped out from the

lower end, using several pumps.

For particularly large cracks, primarily

along the bottom of the culvert, the

applicator used a rubber gasket strip

pushed deep into the crack to reduce the

water flow, thereby enabling him to fill the

gap completely with Patch’n Plug. Xypex

crystalline waterproofing technology is

cement based so it permanently bonds to

concrete and masonry. The active chemicals

in the product diffuse into the substrate

and react with moisture and the

constituents of hardened concrete to generate

a non-soluble crystalline formation

that prevents the penetration of water

from any direction.

Once the 102 meters (335 feet) of leaking

joints were sealed, the applicator then

coated the entire interior (approximately

96 m2) of the culvert with Xypex

Concentrate, which is a cementitious slurry

consisting of Portland cement, finely

graded sand and active proprietary chemicals.

Xypex Concentrate, like Patch’n

Plug, prevents the penetration of water

and other liquids from any direction and

can seal hairline cracks in concrete of up

to 0.4 mm.

Bawax has provided structural waterproofing

for new construction and renovations

for more than 30 years. The firm

was one of the first licensed applicators

of Xypex in Germany and later became a

distributor. Xypex Admix C-1000 NF was

the first and remains the only admixture

sealant approved by Germany’s top certification

organization, Deutsches Institut

für Bautechnik (DIBt).

The culvert repair project was completed

within the six-week school vacation window

and the culvert remains leak free to

this day. In fact, the Hemer public works

department conducted a remote video assessment

of the culvert in the summer of

2018, one year after culvert was repaired.

The culvert showed no signs of leakage.

Fast payback

The successful repair of the culvert cost

Hemer about €74,000 ($85,000 USD) and

required about six weeks of minor traffic

diversions. By contrast, a complete replacement

of the culvert would have required

a complete detour of traffic for up

to four months at a cost of more than

€400,000. In addition, the repair is saving

the city tens of thousands of Euros per

year in extra sewage processing fees.

“We continue to use this same repair process

for other problem situations, such as

leaking manholes and other wastewater

infrastructure, particularly where other repair

procedures or techniques have

failed,” notes Hemer’s Astrid Hanzen.

“The combination of Xypex waterproofing

products and Bawax skilled applicators

provides a cost-effective solution with

minimal downtime.