Back to Search Results

Tunnels

West Gate Tunnel

Melbourne,

Australia

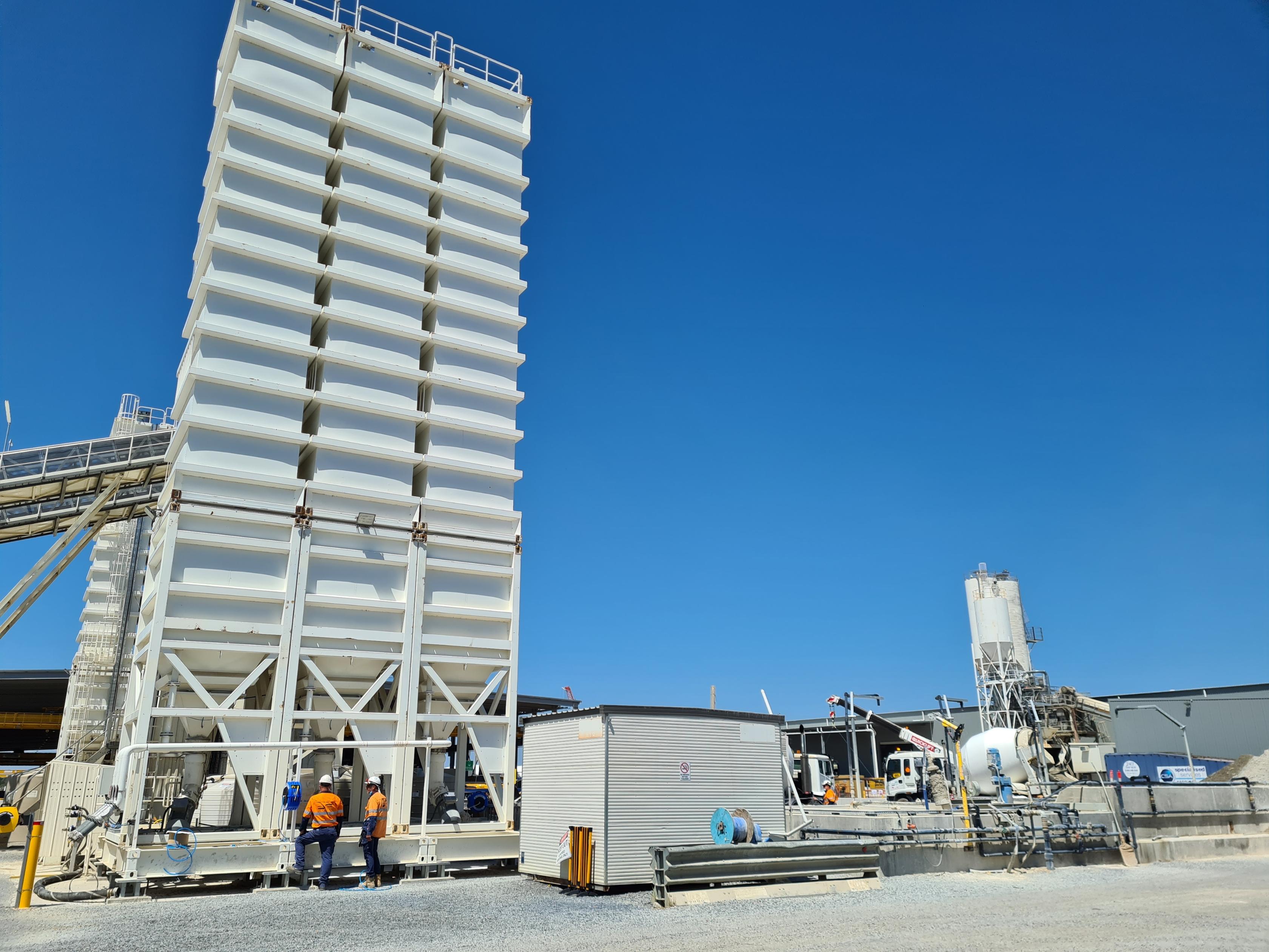

Engineers were concerned about potential adverse effects of carbonation from vehicle emissions on the concrete infrastructure for the West Gate Tunnel project. The general contractor conducted tests on concrete treated with Xypex Admix C-500 and found that the Xypex-treated concrete reported a carbonation effect depth of 0 mm. As a result it was decided to add Xypex Admix C-500 in the concrete for the exhaust ducts to permanently waterproof, enhance durability, and provide resistance to carbonation throughout the concrete's lifespan.

Project Sheet

Project Sheet

PDF

Engineers were concerned about potential adverse effects of carbonation from vehicle emissions on the concrete infrastructure for the West Gate Tunnel project. The general contractor conducted tests on concrete treated with Xypex Admix C-500 and found that the Xypex-treated concrete reported a carbonation effect depth of 0 mm. As a result it was decided to add Xypex Admix C-500 in the concrete for the exhaust ducts to permanently waterproof, enhance durability, and provide resistance to carbonation throughout the concrete's lifespan.

To address this challenge, the project incorporated Xypex Admix C-500, a concrete admixture known for its permanent waterproofing, durability and crack sealing. Admix C-500 consists of Portland cement and various active, proprietary chemicals. These active chemicals react with the moisture in concrete and the by-products of cement hydration to cause a catalytic reaction.

This reaction generates a non-soluble crystalline formation throughout the pores and capillary tracts of the concrete that permanently waterproofs the concrete. The reduced permeability also increases the resistance to carbonation and other chemical attack.

Admix C-500 treated concrete exhibits resistance to extreme hydrostatic pressure, making it suitable for below-grade structures, including deep tunnels. It is incorporated into the fresh concrete without negatively impacting strength, slump, or the air content of the concrete. Admix C-500 is a permanent solution that is non-toxic, does not contain VOCs, and is cost-effective compared to traditional waterproofing methods. As it is added to concrete during batching, it does not require favorable weather like waterproofing membranes and coatings, resulting in a reduced construction schedule.

The incorporation of Admix C-500 into the West Gate Tunnel exhaust ducts successfully waterproofed the concrete without the need to apply any site-applied products while also increasing the service life of the concrete due to greater protection against carbonation from vehicle exhaust.

To address this challenge, the project incorporated Xypex Admix C-500, a concrete admixture known for its permanent waterproofing, durability and crack sealing. Admix C-500 consists of Portland cement and various active, proprietary chemicals. These active chemicals react with the moisture in concrete and the by-products of cement hydration to cause a catalytic reaction.

This reaction generates a non-soluble crystalline formation throughout the pores and capillary tracts of the concrete that permanently waterproofs the concrete. The reduced permeability also increases the resistance to carbonation and other chemical attack.

Admix C-500 treated concrete exhibits resistance to extreme hydrostatic pressure, making it suitable for below-grade structures, including deep tunnels. It is incorporated into the fresh concrete without negatively impacting strength, slump, or the air content of the concrete. Admix C-500 is a permanent solution that is non-toxic, does not contain VOCs, and is cost-effective compared to traditional waterproofing methods. As it is added to concrete during batching, it does not require favorable weather like waterproofing membranes and coatings, resulting in a reduced construction schedule.

The incorporation of Admix C-500 into the West Gate Tunnel exhaust ducts successfully waterproofed the concrete without the need to apply any site-applied products while also increasing the service life of the concrete due to greater protection against carbonation from vehicle exhaust.