Why Xypex for Dams & Irrigation Structures

Meeting the Challenge

Protecting Power & Utilities Structures

The structural integrity of concrete dams and irrigation structures depends on the protection of steel reinforcement from corrosion. Inadequate waterproofing, cracking, joint failure, chemical attack, alkali aggregate reaction and abrasion are problems that will result in the deterioration of concrete. In the short term this can lead to water loss, reduction in water flow and unplanned maintenance costs. Over time, the structural integrity of the concrete is compromised, leading to safety and environmental issues.

With more than 50 years experience in over 90 countries around the globe, Xypex Crystalline Technology has an extensive record in the protection of dams and irrigation structures from hydrostatic pressure, chemical attack and abrasion. Reducing maintenance costs and extending service life in both new and rehabilitated concrete, Xypex is recognized worldwide as a key partner in the water resources industry.

Xypex products play a key role in the waterproofing and protection of concrete against water penetration and aggressive chemical attack – problems typically associated with the reduced service life of concrete dam and irrigation structures.

Water Permeability & Corrosion

The primary purpose of waterproofing concrete dam and irrigation structures is to prevent the intrusion of water into the structure thus protecting the reinforcing steel from the damaging effects of corrosion. The nature of concrete and the problems associated with placement and consolidation means having to deal with permeability issues permitting the penetration of water into the substrate and through to the reinforcing steel. With the presence of oxygen this can initiate corrosion.

Chemical Attack

Dam and irrigation structures are subject to attack from a variety of chemicals whether they be acidic or alkaline, organic or inorganic, man-made or natural. Sulfates may be present in water from upstream soils or mining activity. They react with calcium hydroxide in the concrete to produce an expansive reaction causing spalling and deterioration.

Alkali Aggregate Reaction (AAR)

Dams and irrigation structures are often constructed in remote areas offering a limited choice of aggregates for the concrete mix. Some aggregates react with the alkali hydroxides in concrete, causing expansion and cracking over a period of many years, affecting the structural integrity of the concrete.

Cracking

Cracks in concrete are the most obvious means by which water and damaging chemicals can enter a structure. These cracks are formed in a number of different ways but the most common are drying shrinkage, thermal cracking, strain formed cracks, settlement cracks and plastic shrinkage cracking.

Abrasion

Abrasion occurs in concrete dams, irrigation channels and canals when solids moved along the channel by the flow of water gradually wear away the surface of the concrete. Eventually the reinforcing steel is exposed and corrosion initiates.

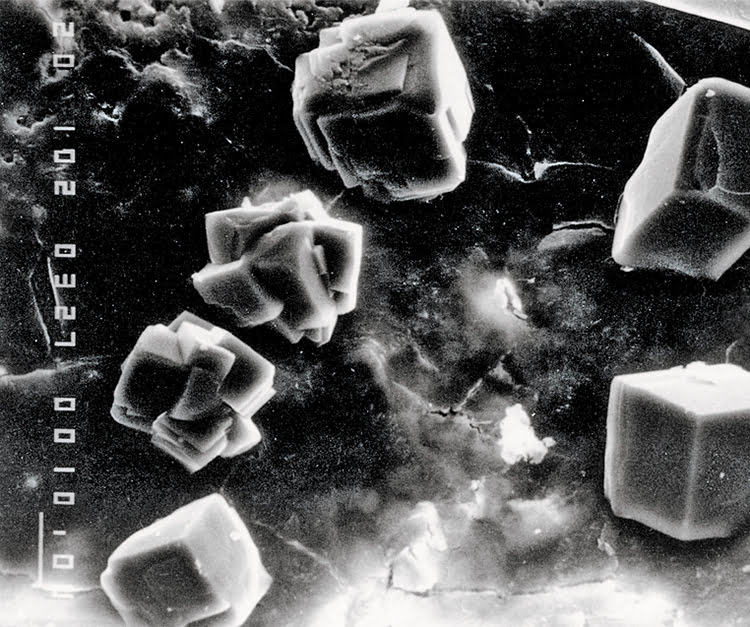

Xypex Crystalline Technology

Xypex products use the natural porosity of concrete and chemical diffusion to penetrate its pores and capillaries. Inside the concrete, Xypex chemicals react with un-hydrated cement particles and the by-products of cement hydration to form a non-soluble crystalline structure deep within the substrate. In this condition, the concrete becomes impermeable, preventing the penetration of liquids and chemicals from any direction even under extreme hydrostatic pressure. The chemical resistant properties of the crystalline structure will help mitigate the attack of sulphates and chlorides. In prolonging the durability of concrete, Xypex has also proven to be effective against the damaging effects of Alkali Aggregate Reaction as well as having the ability to self-heal static cracks up to 0.5 mm (0.02 in). Xypex also improves the freeze-thaw durability of concrete.

The Xypex Advantage

Xypex Crystalline Technology works inside the concrete, thereby avoiding the problems typical of traditional barrier products.

- Permanent and reactivates whenever water is present

- May be applied on negative or positive side of concrete surface

- Self-heals static cracks up to 0.5 mm (0.02 in)

- Not subject to deterioration problems encountered by surface coatings and membranes

- Protects against sulfphate attack

- Resistant to chemical attack

Proven Performance Worldwide

Comprehensive quality systems and standards along with thorough testing in the lab and the field have resulted in Xypex’s highly respected position in the concrete industry. Xypex has been extensively tested by independent testing laboratories in the U.S., Canada, Australia, Japan, Europe and other countries.

Xypex Admix for New Concrete Construction

Xypex Admix is the preferred choice for installing Xypex Crystalline Technology into most new concrete dam and irrigation structures. Because Xypex Admix is blended into the mix at the time of batching, it becomes an integral part of the entire concrete matrix, thus reducing the potentially damaging effects of water penetration, chemical attack and sulfate attack. The addition of Xypex Admix to concrete is a highly effective method of enhancing the durability of concrete structures.

Xypex Admix Advantages

- Permanent integral waterproofing

- Enhances concrete durability

- Value engineering

- Non-toxic

- Non-combustible

- Resists damaging effects of water penetration and chemical attack

Discover the full potential

of Additive products.

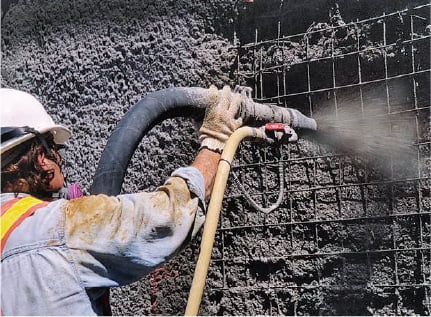

Rehabilitation & Repair

Xypex’s coating systems and repair products enable owners, engineers and contractors to economically and confidently repair structures that have been damaged by water ingress due to hydrostatic pressure, chemical and sulfate attack. Xypex Concentrate and Modified are applied as slurry coats to the surface of the concrete, and are equally effective when applied to both positive and negative sides. Unlike other materials that need a dry substrate, Xypex products require a moist surface to enable the Xypex Crystalline process. Xypex Patch’n Plug, Xypex Concentrate Dry-Pac and Megamix products are specifically designed to permanently repair concrete defects such as static cracks and faulty cold or construction joints. Xypex Megamix returns structural integrity to severely damaged concrete, giving abrasion resistance and maintaining the same protective properties of Xypex-treated concrete.

Xypex Coating Advantages

- Doesn’t require a dry surface

- Apply to either side of the concrete

- Won’t puncture, blister or tear

- No costly surface priming or leveling

- Sealing, lapping or finishing is not required

- No need for protection during backfilling

- Permanent waterproofing

- Enhanced concrete durability

- Doesn’t contain VOCs

- Non-toxic and non-combustible

- Can be applied safely in confined spaces

Other Accessory Products are also available.

SEE XYPEX PRODUCTS

Find the right product

for your project.