Zuidhorn, Netherlands Railway Bridge Replacement

According to Totech project manager Patrick Mallens, the use of Xypex Concentrate to protect the new railway bridge over the Van Starkenborgh Canal (fig 8) not only helped keep the project on schedule, but provided a significant cost savings over the epoxy coating that ProRail normally uses on such projects. “Xypex was ideal for this project,” Mallens notes. “It offered the shortest possible application and curing time, and greatest possible flexibility to accommodate varied weather conditions. The long-term benefits for the railway are also important and include lower maintenance costs and extended service life.

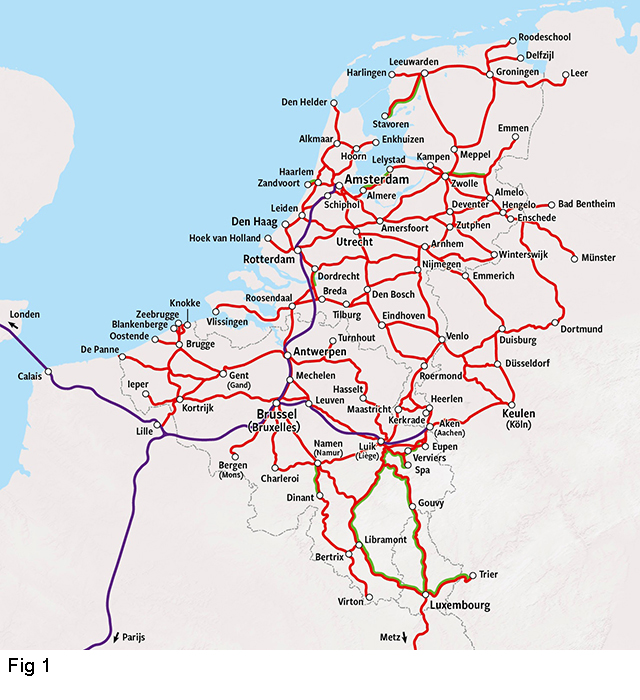

In 2016, the Netherlands’ governmental agency responsible for railway maintenance, ProRail, determined that a critical rail bridge over the Van Starkenborgh Canal in the town of Zuidhorn needed replacement in order to improve canal navigability and to ensure reliable rail traffic between Leeuwarden and Groningen. On weekdays, the single 80-year-old railway bridge was required to handle two passenger trains per hour as well as freight traffic as needed.

According to bridge design firm Arcadis, “The bend in the Van Starkenborgh Canal near Zuidhorn has been widened so that shipping traffic can pass each other unhindered. This has made it necessary to replace the existing railway bridge with a new bridge with a larger span. With the realization of the Bert Swart Bridge (named after the late major of Zuidhorn), the vertical clearance height has also been increased.”

The steel replacement bridge was assembled along the bank of the canal by the German general contractor Max Bögl from parts fabricated in Germany. After a year-long construction project, the new 1,700-ton, 200-meter bridge, was maneuvered into its final position alongside the original bridge, using heavy lift technology such as self-propelled modular transporters (SPMTs), heavy cranes, and barges (fig 2 &3).

Steel-reinforced precast concrete deck slabs were installed on the bridge cross-girders and topped with a cast-in-place concrete surface to provide a solid track base. ProRail’s standards for railway bridges requires a waterproof track deck that is also resistant to chemical attack.

In most cases, ProRail specifies an epoxy coating to protect concrete track beds. However, knowing that the bridge deck would need to be waterproofed in September and that rain was likely, the agency sought an alternative solution. After meeting with Netherlands-based Xypex distributor and applicator Totech, ProRail and contractor Max Bögl selected Xypex Concentrate.

Since Xypex Concentrate is cement based and requires a pre-saturated surface to allow its active chemicals to diffuse into the concrete substrate, mist and rain are actually beneficial. Not only was Xypex Concentrate two to three times less costly than an epoxy coating, it offered the fastest possible application time—less than three days to coat 2,000 square meters. Xypex Concentrate precipitates a chemical reaction with moisture and the by-products of cement hydration to form a non-soluble crystalline formation that permanently seals the concrete and can heal hairline cracks up to 0.4 mm. By preventing the penetration of water and other liquids, Xypex Concentrate also provides chemical resistance properties that mitigate the attack of chlorides, sulfates and the effects of carbonation and alkali-aggregate reaction.

Almost immediately after the application of Xypex Concentrate by Totech (fig 4-7), the contractor was able to install prestressed concrete railroad ties, gravel ballast, and steel rails on the new bridge. Because Xypex Concentrate becomes an integral part of the concrete deck, there is less concern when drilling or attaching fasteners than there would be with conventional coatings or membranes.

According to Totech project manager Patrick Mallens, the use of Xypex Concentrate to protect the new railway bridge over the Van Starkenborgh Canal (fig 8) not only helped keep the project on schedule, but provided a significant cost savings over the epoxy coating that ProRail normally uses on such projects. “Xypex was ideal for this project,” Mallens notes. “It offered the shortest possible application and curing time, and greatest possible flexibility to accommodate varied weather conditions. The long-term benefits for the railway are also important and include lower maintenance costs and extended service life.

Overview

Applicator

Totech, Prorail

Contractor

Max Bögl

Project Type

Bridges

Location

Zuidhorn, Netherlands

PRODUCTS USED

CONCENTRATEApplied as a cementitious slurry to the surface of existing above or below-grade structures to waterproof and protect the concrete against high hydrostatic pressure and aggressive environments.

Specifically formulated for restoration of concrete damaged by microbial induced corrosion, abrasion/erosion and chemical attack.