Wastewater Collection & Treatment

Protecting Critical Wastewater Infrastructure

Sewage conveyance and wastewater collection rank among the most important public health responsibilities in every community. Two common issues with this critical infrastructure are microbial induced corrosion and the infiltration/exfiltration of liquids. Left untreated, these environmental issues lead to rapid deterioration of sanitary systems and failures that are costly to repair and disruptive to everyday life.

Find Projects

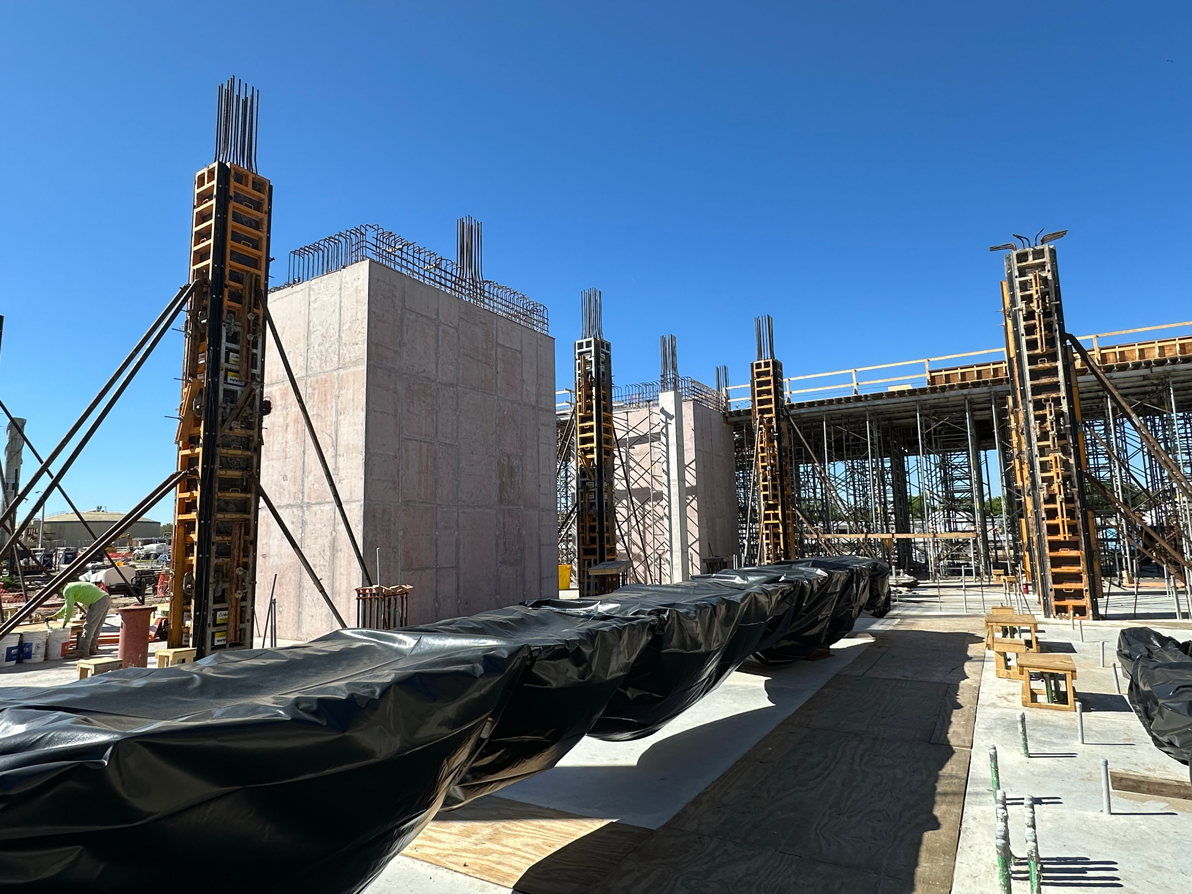

Pendleton-Clemson Regional Wastewater Treatment Plant Expansion

The Town of Pendleton undertook the expansion of the Pendleton-Clemson Regional Wastewater Treatment Plant to increase treatment capacity and improve long-term system reliability for the surrounding service area.

JEA Bio Solids Facility

The JEA Buckman Bio Solids Facility required durable concrete protection for new sludge holding tanks and the overhead structural slab exposed to aggressive wastewater conditions. These structures operate under continuous exposure to hydrogen sulphide and microbial activity that can lead to microbial induced corrosion. The project demanded a long-term solution capable of protecting concrete integrity without reliance on surface applied linings or membranes that require ongoing maintenance.

Saint-Isidore Wastewater Treatment Plant Upgrade

The Municipality of Saint-Isidore initiated an upgrade to its wastewater treatment facility to replace aging infrastructure and comply with updated environmental standards. The modernization involved the construction of new reinforced concrete structures, including a degritter building, a concrete treatment pond, and a pumping station.

.jpg)

Picton Main St Pump Station

On September 1, 2024, the County of Prince Edward completed the construction of a new wastewater pump station in Picton, Ontario. This critical infrastructure project was designed to enhance the municipality's wastewater collection and treatment capabilities. Located near Lake Ontario, the project presented unique waterproofing challenges that demanded innovative solutions.

Plateau Potable Water Reservoir Vaudreuil-Dorion

The construction of a new potable water reservoir aimed to enhance water storage infrastructure with an emphasis on durability and reliability. A key challenge was ensuring that the reservoir’s watertightness and long-term durability would protect the potable water supply from contamination and leakage while withstanding constant water pressure and environmental stresses.