Back to Search Results

General Construction Foundation

| Bridges

Jiangbei Bridge Concrete Rehabilitation

Ningbo City,

China

Jiangbei Bridge is located on Jiangbei Avenue in Ningbo City, Zhejiang Province, and crosses the Yao River. During its construction, it was named Qinglindu Extra Large Bridge, and was later renamed Jiangbei Bridge after completion. The bridge was fully connected on October 30, 1996, and opened to traffic together with Jiangbei Avenue on December 30, 1996.

Project Sheet

Project Sheet

PDF

The total bridge length is approximately 551 m, with a structural configuration of 8 × 25 m + 2 × 35 m + 9 × 25 m prestressed T-beams. The bridge width is 27.5 m, consisting of (from west to east) 1.5 m sidewalk + 24.5 m carriageway + 1.5 m sidewalk. During routine maintenance, irregular fine cracks were found in the prestressed T-beams of the northern approach section. Due to the bridge’s age, localized concrete reinforcement exposure and rust expansion were also observed. Although these issues do not immediately affect structural safety or normal traffic operation, they deteriorate the durability and appearance of the bridge, thereby shortening its service life.

Considering that Jiangbei Bridge has been in service for a long period, and in order to enhance the durability of the prestressed T-beam concrete and extend its service life, it was decided to use the XYPEX Concentrate crystalline slurry coating system for surface rehabilitation and strengthening. XYPEX crystalline technology contains proprietary active chemical ingredients that react with the inherent chemical components and porosity of cementitious materials. Using water as a carrier, these chemicals penetrate into the concrete and react with tricalcium silicate and calcium hydroxide in the cement paste to form insoluble, dendritic calcium silicate hydrates (C–S–H) and calcium aluminate hydrates within the capillary pores.

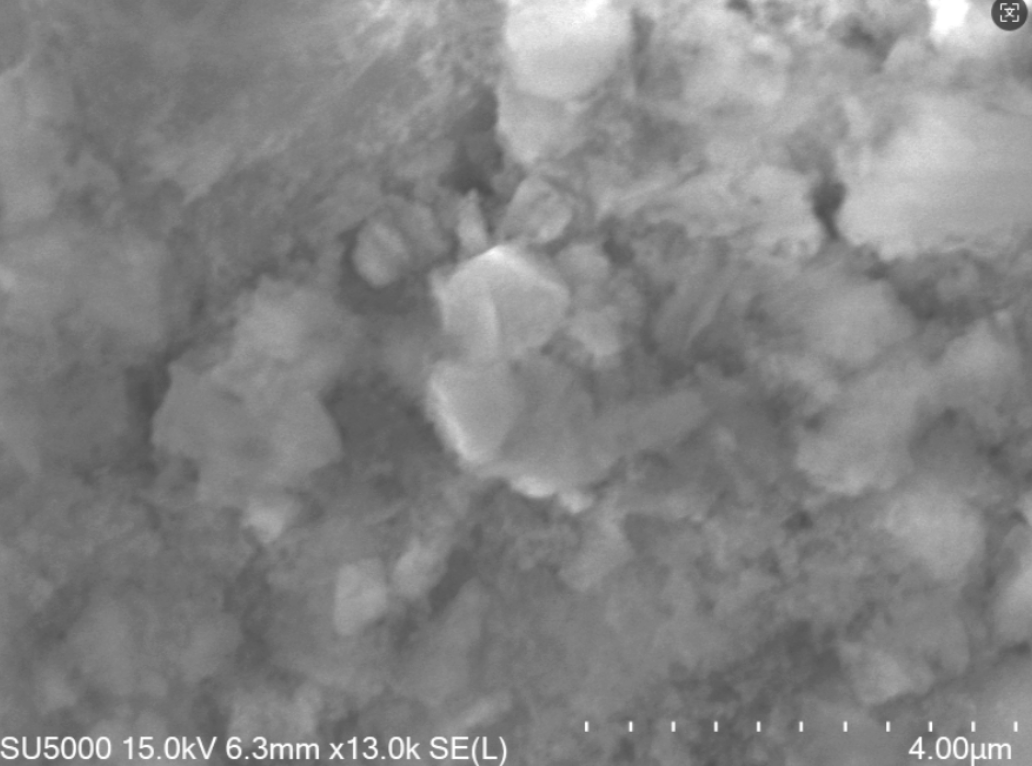

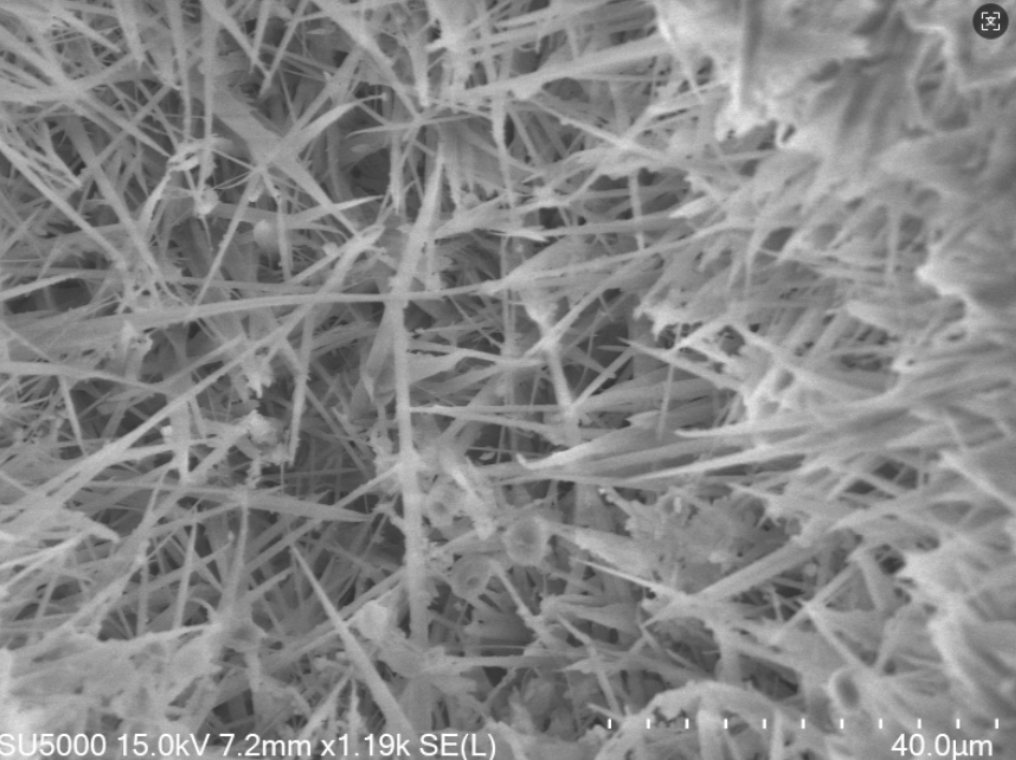

These crystalline formations integrate permanently with the concrete matrix, effectively blocking water and other liquids from any direction, thus providing permanent waterproofing, anti-corrosion protection, and reinforcement of the concrete structure. The repair works were completed on November 23, 2023, and passed inspection. All cracks on the bridge deck were observed to be sealed. After nearly one year of continuous monitoring, the cracks remained closed with no new cracking observed. With the owner’s approval, on November 4, 2024, core samples were taken from both treated areas (with XYPEX coating) and untreated areas at the underside of the T-beam for microstructural examination using a scanning electron microscope (SEM) at 5000× magnification to evaluate crystalline formation.

Within the treated concrete (25 mm depth), fibrous hydration crystals are clearly visible. These formations make the concrete denser, thereby enhancing waterproofing, anti-corrosion, and carbonation resistance. In the untreated concrete (25 mm depth), no fibrous crystalline formations are observed.

Conclusion

Based on the above test results, it can be concluded that using XYPEX materials and application technology for the repair and surface protection of reinforced concrete beams provides significant advantages compared to other materials and methods. The crystalline reaction effectively seals microcracks and capillaries, improving the density, durability, and overall longevity of the bridge structure.

Considering that Jiangbei Bridge has been in service for a long period, and in order to enhance the durability of the prestressed T-beam concrete and extend its service life, it was decided to use the XYPEX Concentrate crystalline slurry coating system for surface rehabilitation and strengthening. XYPEX crystalline technology contains proprietary active chemical ingredients that react with the inherent chemical components and porosity of cementitious materials. Using water as a carrier, these chemicals penetrate into the concrete and react with tricalcium silicate and calcium hydroxide in the cement paste to form insoluble, dendritic calcium silicate hydrates (C–S–H) and calcium aluminate hydrates within the capillary pores.

These crystalline formations integrate permanently with the concrete matrix, effectively blocking water and other liquids from any direction, thus providing permanent waterproofing, anti-corrosion protection, and reinforcement of the concrete structure. The repair works were completed on November 23, 2023, and passed inspection. All cracks on the bridge deck were observed to be sealed. After nearly one year of continuous monitoring, the cracks remained closed with no new cracking observed. With the owner’s approval, on November 4, 2024, core samples were taken from both treated areas (with XYPEX coating) and untreated areas at the underside of the T-beam for microstructural examination using a scanning electron microscope (SEM) at 5000× magnification to evaluate crystalline formation.

Within the treated concrete (25 mm depth), fibrous hydration crystals are clearly visible. These formations make the concrete denser, thereby enhancing waterproofing, anti-corrosion, and carbonation resistance. In the untreated concrete (25 mm depth), no fibrous crystalline formations are observed.

Conclusion

Based on the above test results, it can be concluded that using XYPEX materials and application technology for the repair and surface protection of reinforced concrete beams provides significant advantages compared to other materials and methods. The crystalline reaction effectively seals microcracks and capillaries, improving the density, durability, and overall longevity of the bridge structure.

Overview

Market Segment

General Construction

Location

Ningbo City, China

PRODUCTS USED

Concentrate

+ Show Details

Applied as a cementitious slurry to the surface of existing above or below-grade structures to waterproof and protect the concrete against high hydrostatic pressure and aggressive environments.