Manure Holding Tanks

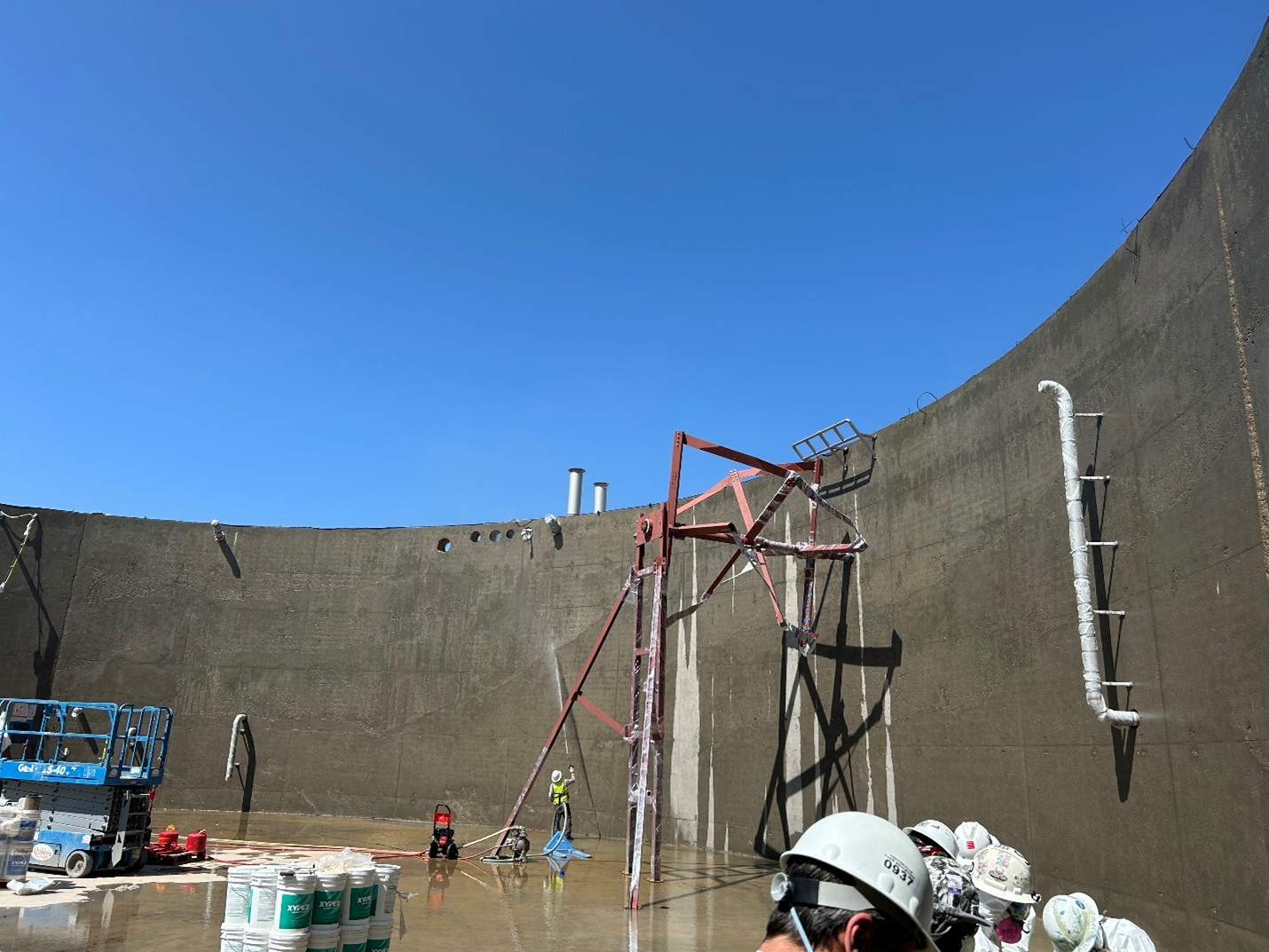

This project involved the application of Xypex crystalline waterproofing across 60,000 sq ft of concrete manure holding tanks in Clovis, New Mexico, for Vanguard Ag, a developer specializing in agricultural waste-to-energy systems. The tanks support anaerobic digestion, a process that breaks down farm and food waste to produce renewable biogas and agricultural byproducts.

Given the harsh operating environment—exposure to manure slurry, hydrogen sulfide (H2S), methane, and fluctuating pH levels—Xypex was selected for its chemical resistance, self-sealing properties, and long-term durability. Sunland Construction, the general contractor, self-performed the application across six tanks using Xypex Concentrate (primary waterproofing), Xypex Modified (enhanced protection in high-stress zones), and Xypex Patch’n Plug (for crack repair prior to treatment). The concrete surfaces were prepared by cleaning, pre-wetting, and repairing defects to ensure optimal crystalline penetration.

Xypex’s unique technology reacts with moisture and unhydrated cement particles to form insoluble crystals, permanently sealing the concrete against water and chemical ingress. Key engineering advantages of this solution include:

• Self-healing capability (sealing cracks up to 0.5mm over time), critical for dynamic wastewater structures.

• Elimination of membrane delamination risks, as the treatment is integral to the concrete.

• Sustainability benefits, including VOC-free composition and extended infrastructure lifespan.

The project was completed successfully, providing Vanguard Ag with a low- maintenance, corrosion-resistant solution tailored to the demands of large-scale anaerobic digestion. Xypex’s performance aligns with USDA and wastewater industry standards, making it a proven choice for agricultural and industrial concrete protection.

Overview

Market Segments

Wastewater Collection

& Treatment

Owner / Developer

Vanguard Ag

Engineer

Vanguard Ag

General Contractor

Sunland Construction

Location

Clovis, New Mexico, USA

PRODUCTS USED

Patch'n PlugFormulated as a crystalline, fast-setting hydraulic cement compound for concrete patching and repair. It stops flowing water in seconds and is used to seal cracks, fill tie-holes and other defects in concrete.

Applied as a cementitious slurry to the surface of existing above or below-grade structures to waterproof and protect the concrete against high hydrostatic pressure and aggressive environments.

Specifically formulated for restoration of concrete damaged by microbial induced corrosion, abrasion/erosion and chemical attack.