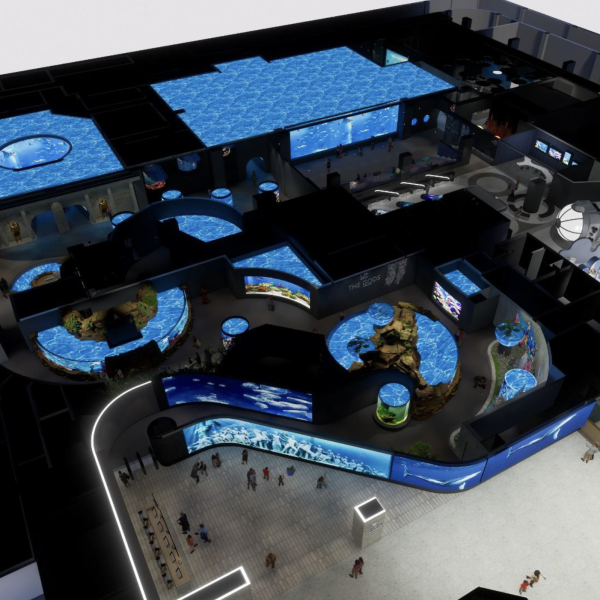

Daejeon Expo Aquarium

The safeguard this new expo aquarium from saltwater corrosion and hydrostatic pressure, the team incorporate:

– 6,500 kg of Xypex Admix C‑1000 NF to deliver permanent waterproofing, chemical resistance, and self-healing microcrack protection

– 2,000 kg of Xypex Concentrate to the joints for precision sealing

– 2,000 kg of Xypex Patch’n Plug for robust seams

The project delivered long-term durability and construction efficiency with a waterproofing solution that was not only technically advanced, but also cost-effective and environmentally safe.

Learn more