Concrete is essential to modern infrastructure but faces challenges due to its porous nature and susceptibility to cracking. This can lead to water ingress, reinforcing-steel corrosion and decreased structural lifespan. This article examines the Xypex Crystalline Waterproofing exclusive and proprietary technology, focusing on its technical performance, environmental sustainability and economic viability.

Technical Performance

A key feature of Xypex crystalline technology is its ability to resist hydrostatic pressure. Unlike surface treatments that repel water only on the surface, Xypex forms deep crystalline structures within the concrete, providing robust protection against high water pressure commonly found in underground structures. When moisture is present, Xypex forms a non-soluble crystalline structure within the interconnected pores of the concrete and becomes a permanent part of the concrete matrix, providing unmatched protection from within the concrete structure.

This not only prevents water ingress but also establishes a self-healing mechanism. Xypex is distinguished as the first concrete waterproofing admixture approved in the European Union by the European Assessment Document (EAD) 260026-00-0301, confirming its capability to withstand intense hydrostatic pressure.

Corrosion Protection

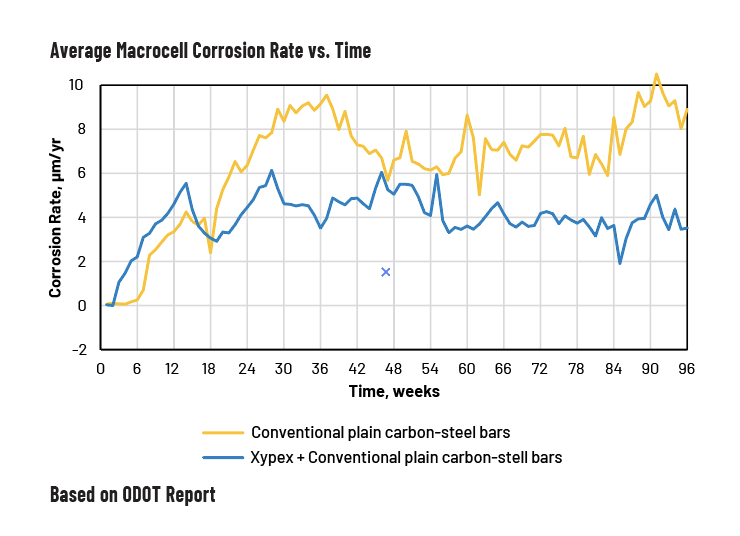

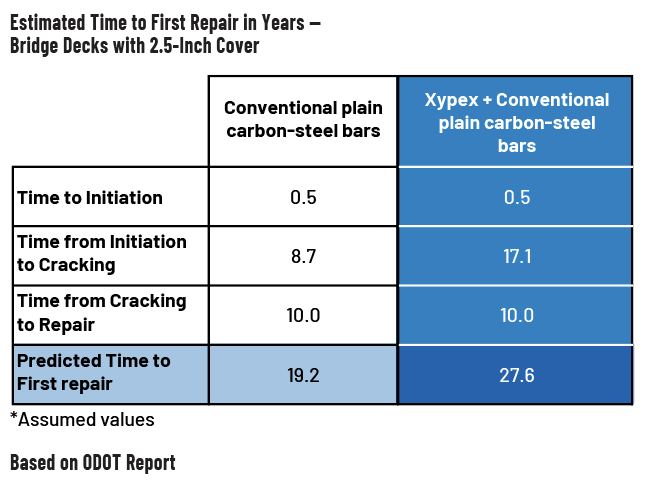

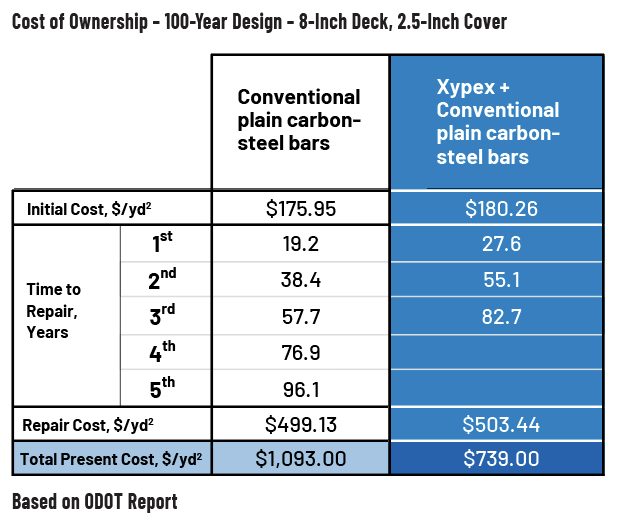

A significant aspect of concrete deterioration is the corrosion of embedded reinforcement. The study “Evaluating the Performance of Existing Reinforcement for Oklahoma Bridges” by the Department of Civil, Environmental & Architectural Engineering at The University of Kansas (ODOT) provides substantial evidence supporting Xypex’s ecacy. The study shows that Xypex-treated concrete reduces rebar corrosion rates by 43% in uncracked concrete and up to 67% in cracked concrete.

Durability Enhancement

Xypex-treated concrete not only prevents water ingress, but also significantly enhances the material’s overall durability. The self-healing properties of Xypex mean that the crystalline formations continue to reactivate whenever water is present, sealing new micro-cracks over the structure’s lifetime. This continual self-healing process extends the concrete’s service life and delays the onset of deterioration mechanisms due to freeze-thaw cycles and chemical attacks.

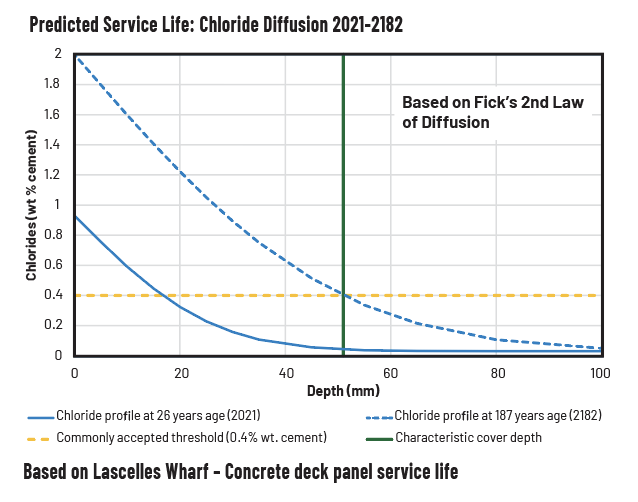

Lascelles Wharf, constructed in 1995, underwent independent third-party tests in 2014 and 2021. The 2014 tests revealed minimal damage, low chloride penetration and no significant carbonation, estimating a service life of 164 years using Fick’s 2nd Law of diffusion. The 2021 tests confirmed these findings and showed even better results, with zero carbonation and lower average chloride penetration.

The same predictive modeling now estimated a service life of 187 years. These results demonstrate that Xypex- treated concrete improves through time due to continuous crystal growth when in contact with water, enhancing durability and reducing maintenance needs.

The ODOT study also highlights that Xypex significantly extends the time before the first repair is needed, leading to reduced maintenance costs.

Environmental Sustainability

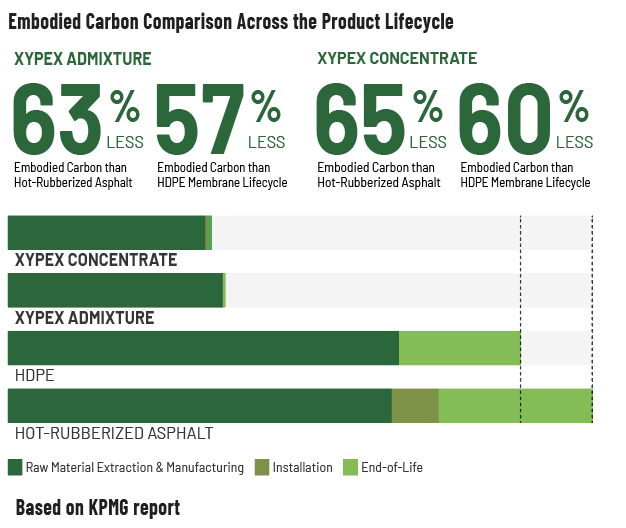

Cement production contributes significantly to global CO2 emissions, but Xypex offers a solution to mitigate this impact. According to the KPMG report, “Embodied Carbon Assessment: A Technical Comparison of the Carbon Intensity of Xypex’s Crystalline Waterproofing to Alternatives,” Xypex significantly reduces the embodied carbon footprint compared to traditional waterproofing methods. Additional environmental benefits include the following:

∙ No VOCs nor Red-List Chemicals: Xypex products are free from volatile organic compounds and harmful chemicals, minimizing environmental and health impacts.

∙ NSF 61 Certification: Xypex products are certified for use in potable water systems.

∙ Type 3 Environmental Product Declarations (EPDs) and Health Product Declarations (HPDs): Provide transparency regarding the environmental and health impacts of Xypex products.

∙ LEED Credits: Xypex contributes to achieving LEED certification, supporting sustainable building practices.

Economic Sustainability

The economic benefits of Xypex are highlighted by lifecycle cost analyses conducted by the Oklahoma Department of Transportation (ODOT). Due to the extended durability and reduced maintenance costs, these analyses show that Xypex offers significant long-term savings, with ownership costs being 30% lower compared to projects that do not use Xypex.

Conclusion

Xypex crystalline waterproofing technology enhances concrete durability through its advanced crystalline formation mechanism. Its environmental and economic benefits—supported by rigorous third-party tests—make Xypex a valuable choice for both environmentally and economically sustainable projects. The technology’s lower embodied carbon, extended service life and reduced lifecycle costs align with the goals for sustainable engineering practices.